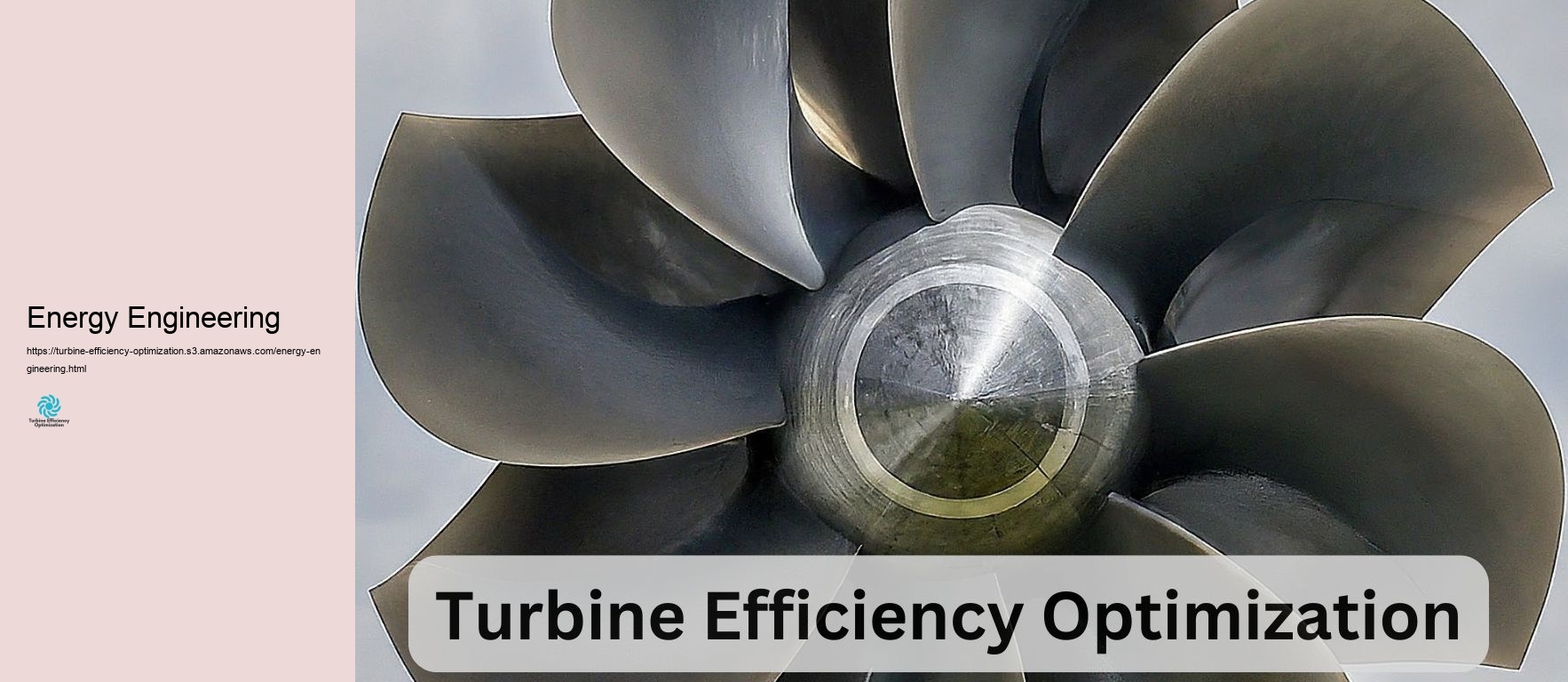

Turbine efficiency is an essential idea in the field of power manufacturing and mechanical style. It describes the ability of a turbine to transform the power of a relocating fluid (such as water, vapor, or gas) right into beneficial mechanical task. Energy Engineering Understanding the principles of turbine efficiency is essential for engineers, energy experts, and anyone associated with the style, procedure, or upkeep of power generation systems. At its core, turbine efficiency is an action of how successfully a turbine can remove power from the liquid travelling through it. This efficiency is generally disclosed as a part, with greater parts suggesting far better performance. In a suitable globe, a turbine would absolutely be able to change 100% of the liquid power into mechanical work. Nevertheless, actually, numerous elements contribute to power losses, leading to performances that are constantly much less than 100 %. Among the key variables affecting turbine efficiency is the layout of the turbine itself. The kind, size, and plan of the turbine blades play a crucial duty in figuring out '' specifically how appropriately the liquid power can be used. Modern turbine formats usually include ingenious wind resistant or hydrodynamic principles to enhance the blood circulation of liquid using the turbine, minimizing losses and maximizing energy removal. The sort of liquid made use of in the turbine in addition substantially effects its efficiency. Heavy steam wind generators, for instance, are generally used in thermal nuclear power plant and have different efficiency considerations contrasted to hydroelectric generators or wind wind turbines. The domestic or business buildings of the fluid, such as its density, temperature degree, and stress, all impact just how effectively it can transfer power to the turbine blades. An additional crucial aspect of turbine efficiency is the concept of thermodynamic cycles. In many power generation systems, generators become part of a larger thermodynamic cycle, such as the Rankine cycle in steam nuclear reactor or the Brayton cycle in gas wind turbines. The total efficiency of the system depends not just on the turbine's efficiency yet on simply how well it integrates with the different other elements of the cycle, such as boilers, condensers, and compressors. The operating problems of the turbine similarly play a significant function in its efficiency. Components such as the inlet temperature and stress of the fluid, the rotational rate of the turbine, and the great deals on the turbine can all influence its efficiency. Wind turbines are typically created to operate most effectively at specific conditions, called the format factor. Running a turbine away from its design point can reason minimized efficiency. Losses within the turbine system include in minimized efficiency. These losses can occur in different kinds, such as massaging losses in bearings and seals, wind immune losses as a result of disturbance and dividing of circulation, and leak losses where fluid bypasses the turbine blades without doing beneficial work. Minimizing these losses via careful style and upkeep is crucial for making ideal use turbine efficiency. The concept of isentropic efficiency is often used when discussing turbine efficiency. This contrasts the actual work outcome of the turbine to the appropriate work result that would be accomplished if the procedure were relatively simple to repair and adiabatic (no heat transfer). The isentropic efficiency gives an activity of just how close the turbine problems exceptional efficiency and is an important device for contrasting various turbine layouts or running problems. Product selection is an extra vital factor to consider in turbine efficiency. The materials made use of for turbine blades and other components need to withstand heats, tension, and worries while preserving their kind and efficiency. Advanced materials and layers can boost turbine efficiency by allowing for higher running temperature levels, reducing damages, and lowering thermal losses. The scale of the turbine can also influence its efficiency. Typically, larger generators tend to be extra effective than smaller sized ones as a result of reduced family member location and minimized symmetrical losses. Nonetheless, this need to be well balanced versus different other elements such as rate, functionality, and certain application demands. Maintenance and practical methods considerably impact turbine efficiency with time. Typical upkeep, consisting of cleaning up, examination, and alternative of utilized components, is essential for preserving excellent efficiency. Additionally, appropriate functional procedures, such as progressive start-up and closure procedures and adherence to advised running specifications, can help keep turbine efficiency and increase its life-span.

specialists need to take into consideration all these facets to style, operate, and keep generators that accomplish the best practical efficiency. As innovation stays to advancement and our understanding of liquid characteristics and power conversion expands, we can anticipate much more remodellings in turbine efficiency, including in a lot more sustainable and efficient power production systems worldwide.

Secret aspects affecting turbine efficiency consist of a range of technological, environmental, and useful factors to consider that collectively find out the efficiency and efficiency of both gas and wind turbines. These aspects are essential in enhancing the efficiency of wind turbines, which are vital in power generation, whether via changing kinetic wind power right into electrical power or using the thermal power from fuel melting in gas wind turbines. For gas wind turbines, among one of one of the most significant elements impacting performance is the ambient air temperature level and website altitude. Gas wind turbines are air-breathing engines, suggesting that the thickness and mass circulation of the air consumption straight effect their efficiency. Greater ambient temperature level degrees lower air thickness, resulting in reduced mass circulation and, subsequently, reduced power outcome. Similarly, greater altitudes cause reduced air pressure, a lot more decreasing air thickness and affecting turbine efficiency. Therefore, understanding and minimizing the impacts of these ecological problems with design aspects to consider or useful adjustments is critical for preserving ideal performance. Moisture is an added ecological element that effects gas turbine performance. Damp air is much less thick than dry air, which can reduced the mass flow rate via the turbine and reduction power end result. This aspect is especially significant in areas with high wetness degrees, where the efficiency of gas wind generators can be jeopardized. To counteract these results, some generators are gotten ready with inlet air cooling systems, such as evaporative colders or refrigerators, to boost air thickness and boost efficiency. The kind and premium of gas made use of in gas wind turbines additionally play a crucial role in recognizing efficiency. Different gas have differing calorific worths, structures, and melting attributes, each of which influence the thermal efficiency and power result of the turbine. Making certain that the gas satisfies certain top quality needs and works with the turbine's layout is important for completing optimum efficiency. Furthermore, utilizing ingenious fuel heater can improve the blended cycle efficiency by improving the power product of the gas. Mechanical losses, such as rubbing between relocating parts like bearings and seals, can also influence turbine efficiency. These losses are typically reduced throughout the design stage with accuracy design and utilizing high-grade materials. Routine upkeep is essential to make certain that these aspects stay in great problem, therefore minimizing mechanical losses and preserving efficiency. In the context of wind generators, wind speed and directions are one of one of the most important elements impacting efficiency. Wind generators transform the kinetic energy of the wind into electric power, and the amount of power caught is straight proportional to the wind price. Also tiny boosts in wind rate can bring about considerable gains in power result. As a result, choosing websites with normal and solid wind problems is important for taking full advantage of turbine efficiency. The orientation of the turbine relative to the wind instructions also influences efficiency, calling for resilient yaw control systems to preserve optimum positioning. Air thickness and temperature similarly impact wind turbine efficiency, similar to gas generators. Higher air thickness increases the mass circulation rate through the turbine, improving power result. Conversely, greater temperature degrees can produce thermal growth of materials, possibly affecting the efficiency of the generator and other electric parts. Audit for these variants via design and functional methods is crucial for maximizing efficiency. Turbulence and wake results are included factors that can influence wind turbine efficiency. Disruption defines the disorderly fluctuations in wind speed and guidelines, which can create resonances and stress on turbine components, possibly causing exhaustion and noise. Wake results take place when the wind rate and guidelines are changed by the visibility of upstream wind generators, influencing the efficiency of downstream systems in a wind cattle ranch. To ease these influences, cautious prep work of turbine format and spacing, in addition to cutting-edge control methods, are needed. Control and optimization approaches are vital for both gas and wind wind turbines to accomplish optimum performance. These strategies include utilizing innovative solutions and control systems to take care of numerous operational specifications, such as blade pitch, blades price, and generator torque. By constantly keeping track of and readjusting these criteria based upon real-time details, generators can run extra efficiently and dependably, making ideal use of power outcome and lowering degeneration. Lastly, ecological and social effects are essential considerations in turbine efficiency. For wind wind turbines, aspects such as land use, wildlife communications, and noise levels can influence public acceptance and regulatory consistency. For gas generators, exhausts and resource intake are essential environmental problems. Managing these affects using lasting practices and stakeholder participation is crucial for the lasting functionality of turbine jobs. The efficiency of generators, whether gas or wind, is influenced by an elaborate communication of environmental, technological, and functional elements. By understanding and enhancing these aspects, drivers can boost efficiency, stability, and sustainability, making sure that generators continue to play a vital feature in the international power landscape. Whether with innovative control systems, tactical site option, or ingenious style solutions, the pursuit of optimal turbine performance is a dynamic and persisting treatment that requirements continual adjustment and renovation.

Boost turbine performance and efficiency with advanced optimization techniques! Discover the latest strategies in design, materials, and technology to maximize energy output and minimize losses. Stay ahead in the evolving landscape of power generation.https://t.co/pZr0jaoH1i

— Turbine Training And Operation (@turbinetraine) August 25, 2024

Enhancing turbine efficiency is an essential goal in various sectors, including power generation, aerospace, and production, as it straight affects performance, cost-effectiveness, and environmental sustainability. Advanced techniques for turbine efficiency improvement concentrate on maximizing layout, products, and useful techniques to make ideal use of power result while lessening losses. Right below, we check out numerous innovative strategies that are changing turbine innovation and pushing the borders of efficiency. Amongst the most trusted ways to boost turbine efficiency is with wind resistant optimization. This involves fine-tuning the layout of turbine blades to decline drag and increase lift, subsequently enhancing the conversion of kinetic power from wind or heavy steam right into power. Computational fluid attributes (CFD) simulations play a crucial responsibility in this process, enabling developers to layout air circulation patterns and recognize locations for improvement. Plant optimization Advanced blade formats, such as those with twisted or conical types, can significantly improve wind resistant efficiency. Additionally, including energised circulation control contemporary innovations, such as limit layer suction or blowing, can better reduce wind resistant losses and increase efficiency. The growth of sophisticated materials is another necessary factor in improving turbine efficiency. High-performance products, such as superalloys and ceramic matrix composites, give exceptional toughness, warmth resistance, and corrosion resistance, making it feasible for wind turbines to run at higher temperature degrees and anxiety. This is particularly important in gas turbines, where increased running temperature degrees can produce greater thermal efficiency. In addition, making use of light-weight products, such as carbon fiber compounds, can minimize the total weight of turbine parts, lowering inertia and increasing reaction times. Advancements in additive manufacturing, or 3D printing, in addition make it possible for the production of complicated, enhanced geometries that were previously unattainable, even more improving material performance. Reputable air conditioning is needed for maintaining turbine efficiency and prolonging component life-span. Advanced cooling down approaches, such as transpiration cooling down and motion picture cooling, are being established to manage the high thermal tons experienced by turbine blades and different other components. Transpiration cooling involves the circulation of a cooling liquid using a permeable product, providing uniform cooling throughout the surface area. Flick a/c, on the other hand, involves the shot of a slim layer of coolant over the surface of the component, creating a safety barrier versus hot gases. These strategies help maintain ideal operating temperature levels, reduced thermal tension, and quit material deterioration, eventually boosting turbine efficiency. The integration of ingenious control systems and digital modern-day technologies is reinventing turbine efficiency. Modern control systems use real-time data from picking up systems and sophisticated solutions to boost turbine treatment dynamically. This includes changing blade pitch, rotational price, and various other criteria to adjust to altering eco-friendly problems and whole lots demands. Digital twins, which are electronic reproduction of physical turbines, make it possible for constant security and anticipating maintenance, permitting drivers to recognize possible issues before they lead to substantial efficiency losses. Machine learning and expert system are furthermore being leveraged to assess big quantities of useful information, giving understandings that drive a lot more efficiency improvements. Integrating crossbreed systems and renewable resource resources can increase general turbine efficiency and sustainability. For example, integrating wind generators with photovoltaic panels or energy storage space systems can offer a much more protected and reliable power result, decreasing dependence on nonrenewable fuel sources. When it comes to gas generators, integrating with sustainable gas, such as hydrogen or biofuels, can reduce carbon exhausts while maintaining high efficiency. Moreover, crossbreed systems that incorporate numerous types of wind generators, such as wind and hydro, can optimize power capture and usage, additionally enhancing efficiency. Regular upkeep and tracking are essential for sustaining turbine efficiency progressively. Advanced evaluation gadgets and techniques, such as resonance assessment and thermography, permit early discovery of damages, discrepancies, and other issues that can effect performance. Accomplishing a hostile maintenance technique, continual by expecting analytics, can minimize downtime and expand the practical life-span of turbine parts. Remote tracking systems allow continuous oversight of turbine efficiency, making it possible for prompt treatments and adjustments to keep suitable efficiency. Enhancing turbine efficiency is not only a technical barrier yet likewise an environmental and economic crucial. A lot more reliable turbines eat a lot less fuel and create fewer exhausts, contributing to a decrease in greenhouse gases and other toxins. This straightens with international efforts to fight climate adjustment and change to cleaner power resources. Economically, higher efficiency translates to reduce functional expenses and boosted competition, as chauffeurs can create much more power with the very same sources. As a result, economic investment in innovative turbine developments is a tactical problem for both market leaders and policymakers. Looking ahead, several arising trends and innovations hold guarantee for added enhancing turbine efficiency. The development of smart items with adaptive homes can cause self-healing components that maintain efficiency under severe problems. Dope in nanotechnology might result in coverings that reduce rubbing and use, much more expanding part life. Moreover, the exploration of novel turbine designs, such as bladeless or vertical-axis wind turbines, can usage new paths for efficiency gains. As research and development efforts proceed, the prospective for improvements in turbine advancement remains to be significant, driving progression towards an added sustainable and dependable power future. Enhancing turbine efficiency is a multifaceted undertaking that require a mix of advanced style, products, and functional approaches. By leveraging advanced modern-day innovations and advanced strategies, the sector can attain substantial gains in efficiency, sustainability, and cost-effectiveness. As the requirement for cleaner and added reliable power remedies expands, the pursuit of turbine efficiency will certainly stay a vital emphasis for researchers, designers, and policymakers alike, creating the future of power generation and usage.

Keeping optimal turbine treatment is vital for making certain reliable power production, minimizing downtime, and expanding the life expectancy of these complex equipments. Reputable maintenance approaches are necessary for nuclear power plant, wind ranches, and commercial facilities that depend upon generators for their procedures. By accomplishing an extensive maintenance method, drivers can take full advantage of efficiency, decrease expenditures, and increase complete dependability. Among the fundamental maintenance approaches for optimum turbine procedure is the implementation of a durable predictive maintenance program. This technique usages innovative keeping track of modern-day innovations and information analytics to anticipate feasible concerns prior to they produce failings or considerable efficiency damage. Noticing units and keeping an eye on systems are mounted throughout the turbine to collect real-time information on different requirements such as vibration, temperature level, stress, and oil problem. This details is after that examined taking advantage of sophisticated solutions and artificial intelligence methods to recognize patterns and problems that might suggest establishing troubles. Predictive maintenance enables drivers to timetable upkeep tasks based upon the real condition of the devices as opposed to depending exclusively on taken care of time periods. This technique aids stay clear of unexpected break downs, decreases unneeded maintenance, and enhances making use of sources. By handling problems early, vehicle drivers can stay clear of a lot more considerable and pricey dealings with down the line, at some point boosting the turbine's overall reliability and efficiency. Routine assessments and issue assessments type one more crucial component of efficient turbine upkeep strategies. These analyses ought to be done at established periods and consist of both visual evaluations and non-destructive screening methods. Aesthetic inspections can identify apparent signs of wear, damages, or degeneration, while non-destructive testing techniques such as ultrasonic screening, magnetic piece evaluation, and eddy existing testing can place surprise flaws or inner troubles in essential components. Throughout these assessments, certain passion ought to be paid to high-stress locations and components identified to be prone to put on or falling short. This consists of turbine blades, bearings, transmissions, and seals. By identifying and attending to prospective issues early, motorists can stay clear of small problems from increasing right into significant failings that can result in extended downtime and significant repair expenditures. Implementing an extensive lubrication keeping track of program is essential for preserving optimal turbine operation. Appropriate lubrication is critical for reducing rubbing, dissipating warmth, and safeguarding elements from wear and degeneration. This program ought to consist of regular oil evaluation to keep track of the problem of lubricating substances and identify any type of kind of signs of contamination or degeneration. Oil instances should be taken and reviewed at regular durations to track alterations in thickness, acidity, and the visibility of wear little bits or contaminants. Based upon the outcomes of oil analysis, drivers can recognize when oil adjustments or purification are necessary, making sure that the turbine always runs with neat, excellent lubricating compounds. In addition, the lubrication program should certainly contain correct storage and taking care of therapies for lubricating substances to prevent contamination and maintain their efficiency. Resonance monitoring and analysis is one more crucial element of turbine maintenance techniques. Extreme resonance can suggest different troubles, including discrepancy, imbalance, birthing wear, or loosened up parts. By constantly monitoring resonance degrees and patterns, operators can area developing troubles early and take rehabilitative task prior to they reason much more serious damages or failure. Advanced vibration analysis strategies, such as spectral evaluation and orbit tales, can offer thorough understandings right into the nature and location of possible concerns. This information allows maintenance teams to concentrate their campaigns on specific elements or locations of worry, enhancing the efficiency and efficiency of maintenance'' activities. Thermal imaging is one more crucial tool in the upkeep toolbox for optimal turbine procedure. Normal thermal assessments can find hot spots or unusual temperature degree patterns that may suggest problems such as insulation malfunction, electric faults, or bearing problems. By identifying these concerns early, drivers can secure against potential failings and optimize the turbine's thermal efficiency. Performing a durable additional components keeping an eye on system is required for lowering downtime and ensuring quick response to upkeep requirements. This system ought to include a detailed supply of essential parts, with clear requirements for supply degrees, reordering treatments, and storage problems. By protecting an ample supply of important spare parts on-hand, motorists can considerably decrease the moment asked for to full repair services and return the turbine to solution. Training and ability advancement for maintenance staff members is a critical yet usually ignored element of trusted turbine maintenance methods. Ongoing training programs require to be executed to ensure that upkeep team are existing with one of the most approximately date technologies, best techniques, and safety procedures. This includes both technical skills attached to turbine maintenance and soft capacities such as analytic and interaction. Regular performance screening and efficiency tracking are essential for keeping suitable turbine treatment. These examinations can assistance acknowledge any sort of degeneration in performance with time and enable drivers to take restorative action to recover the turbine to capped efficiency. Efficiency evaluating needs to include measurements of power result, gas intake, and discharges levels'., along with analyses of private component performances. Executing a digital upkeep management system (CMMS) can significantly improve the performance of turbine upkeep techniques.

Innovative advancements in turbine efficiency optimization are altering the landscape of power manufacturing, offering brand-new methods to boost performance, lower ecological impact, and boost the sustainability of power generation systems. As around the world need for efficient and tidy energy choices remains to climb, growths in turbine modern-day technology are happening progressively important. These advancements expand a range of locations, including items scientific research, digital modern technology, shedding procedures, and wind resistant design, each contributing to the complete efficiency and efficiency of generators utilized in countless applications, from power plants to wind farms. Among the most substantial growths in turbine efficiency optimization is utilizing sophisticated materials and finishes. Generators run under severe issues, with heats and stress that traditional materials can not stand up versus without degrading. Developments in products scientific research have caused the improvement of superalloys, especially those based upon nickel, which maintain their toughness and safety at raised temperature level degrees. These materials lengthen the life-span of turbine elements and make it possible for them to run at higher efficiencies. Furthermore, thermal barrier finishings (TBCs), such as advanced ceramic substances, are put on turbine components to shield them from warm and boost their sturdiness. These coverings function as insulators, keeping the steel components cooler and boosting their efficiency under harsh troubles. Additive making, or 3D printing, is changing the making and upkeep of turbine elements. This development allows the manufacturing of intricate, high-precision components that are hard or challenging to make making use of conventional approaches. Additive manufacturing enables quick prototyping, allowing engineers to immediately create, examination, and improve turbine components, raising the improvement process. The ability to generate components as needed reductions the need for large supplies of extra components and lessens downtime, as substitute elements can be manufactured and set up quickly. Furthermore, additive production facilitates the manufacturing of components with complex geometries that maximize air flow and cooling within the turbine, better increasing efficiency and lowering thermal stress and anxiety. The integration of digital developments into turbine procedures has in fact opened up brand-new methods for efficiency optimization. Digital doubles, on the internet reproductions of physical wind turbines, permit drivers to mimic and watch on turbine efficiency in real-time. By examining data from noticing units and electronic doubles, anticipating maintenance algorithms can anticipate when a turbine part is probably to fall short, allowing upkeep to be organized at optimal times. This positive strategy reduces downtime and maintenance costs while making sure that generators run at peak efficiency degrees. Anticipating upkeep not just expands the life-span of turbine parts however in addition makes best use efficiency by quiting unexpected failings and making best use of functional specs. Technologies in melting advancement are crucial to boosting turbine efficiency and reducing eco-friendly impact. Typical burning processes in generators generate nitrogen oxides (NOx), damaging pollutants that add to air contamination. Developers have established low-NOx combustors that decrease NOx growth by enhancing the burning procedure. These ingenious combustors make use of strategies such as lean-burn techniques and enhanced fuel-air mixing to reduction wears down without threatening efficiency. As the world changes to cleaner power sources, hydrogen is becoming an appealing gas for wind turbines. Hydrogen melting produces just water vapor as a byproduct, doing away with CARBON DIOXIDE exhausts. Technologies in hydrogen shedding modern technology are making it possible for wind generators to run efficiently with this neat fuel, adding to an extra lasting power landscape. The wind immune design of turbine blades plays a crucial function in developing the efficiency and efficiency of both gas and wind generators. Breakthroughs in the rules of the rules of aerodynamics and blade format have in fact brought about substantial improvements in turbine efficiency. Designers make use of computational liquid dynamics (CFD) and 3D printing to produce aerodynamically improved blade designs that boost the circulation of air and gases via the turbine, minimizing power losses and boosting total efficiency. In wind turbines, variable pitch and spin designs enable blades to adjust dynamically to changing wind problems, maximizing efficiency and decreasing mechanical tension. These technologies in blade style boost the efficiency and life expectancy of wind turbines, making them more affordable with traditional power resources. The assimilation of renewable energy sources is an extra area of growth aimed at boosting turbine efficiency and sustainability. Crossbreed systems that incorporate generators with renewable energy sources, such as solar or wind, can boost general energy production and reduced dependence on fossil fuels. These systems take advantage of the corresponding nature of various power resources to supply an extra secure and credible power supply. As an example, incorporating wind generators with photovoltaic panels can cancel durations of lowered wind with solar energy making, ensuring a regular energy supply. This assimilation not simply increases the efficiency of power systems nonetheless in addition sustains the shift to an extra lasting energy future. Innovative modern-day technologies in turbine efficiency optimization are driving significant innovations in the power market. By leveraging developments in products clinical research, electronic modern-day technology, combustion treatments, and aerodynamic style, wind generators are becoming added effective, trusted, and eco-friendly. These developments are important for pleasing the growing need for neat and efficient energy services and play an important responsibility in the global change to lasting power systems. As {research and development proceed, the potential for much more improvements in turbine modern-day innovation continues to be big, assuring a future of also better efficiency and sustainability in power manufacturing.

Maximizing turbine layout for optimal efficiency is a multifaceted carrying out that entails a deep understanding of wind immune concepts, item scientific research, thermodynamics, and proceeded style methods. Whether managing gas wind generators used in nuclear power plant and airplane or wind turbines utilizing renewable energy, the unbiased is to convert power resources right into mechanical or electrical power with the highest possible possible efficiency. Completing this ask for a considerable technique that thinks of every component of the turbine's layout, from the shape and items of the blades to the setup of the entire system. For gas wind turbines, efficiency optimization beginnings with the design of the compressor and turbine blades. These blades require to be completely crafted to withstand high temperatures and stress while lowering wind resistant drag. Advanced computational fluid characteristics (CFD) simulations are employed to model air circulation over the blades, permitting designers to refine their form for optimal performance. Using high-performance products, such as advanced alloys and porcelains, allows blades to run at higher temperature levels, which is vital for boosting thermal efficiency. Furthermore, including cooling down modern technologies, such as movie cooling or transpiration cooling down, aids preserve blade integrity under severe problems, a lot more improving efficiency. The burning chamber is one more critical element in gas turbine style. It should be created to guarantee complete and effective burning of the gas, minimizing exhausts and maximizing power output. Innovations such as lean-burn burning technology, which reductions the amount of excess air in the burning treatment, can substantially increase efficiency and reduce nitrogen oxide discharges. Additionally, the integration of advanced control systems enables exact policy of fuel and air combinations, improving shedding conditions in real-time based upon operating criteria. In the context of wind generators, enhancing layout for optimal efficiency consists of a concentrate on the rotor blades, which are accountable for capturing the kinetic power of the wind. The wind immune shape of the blades is important; they ought to be created to take full advantage of lift while minimizing drag. This regularly entails using airfoil forms that are made the most of for particular wind conditions. Developers usage wind flow screening and CFD simulations to make improvements blade layouts, guaranteeing they execute effectively throughout a range of wind prices. Furthermore, using light-weight composite items, such as carbon fiber or fiberglass, reductions the general weight of the blades, permitting them to respond a lot more dynamically to alterations in wind problems and enhancing general efficiency. The elevation and positioning of wind generators are furthermore essential think about maximizing efficiency. Taller towers enable generators to accessibility better wind speeds, which are usually a lot more regular and efficient. Web site selection, because of that, involves cautious analysis of wind patterns and topography to ensure wind generators are located where they can record one of the most power. In wind cattle ranches, the format of generators ought to be purposefully designated to lessen wake impacts, where the disruption created by one turbine influences the efficiency of others downwind. Energy Engineering By making the most of the spacing and placement of wind generators, power capture can be made ideal use throughout the entire ranch. Control systems play an important role in optimizing turbine efficiency, both for gas and wind wind turbines. Energy Engineering For gas generators, innovative control systems watch on and readjust criteria such as fuel flow, air consumption, and exhaust temperature level degrees to maintain optimum operating problems. Plant operations These systems can respond to changes in demand and ecological problems, making certain that the turbine operates at peak efficiency at all times. In wind generators, control systems adjustment the pitch of the blades and the yaw of the nacelle to straighten with transforming wind instructions and speeds, optimizing power capture while lessening mechanical anxiety. Power storage area and crossbreed systems are becoming important factors to consider in turbine style, specifically for renewable energy applications. Including power storage room solutions, such as batteries or flywheels, can aid ravel the variability of wind power, storing excess power throughout periods of high manufacturing and releasing it when demand is higher. Hybrid systems that integrate wind generators with various other power sources, such as photovoltaic panels or gas wind generators, can provide even more regular power result and boost total efficiency. The mix of digital developments and details analytics is transforming turbine design and procedure. Utilizing sensing systems and IoT devices makes it possible for real-time monitoring of turbine efficiency, providing crucial information that can be made use of to enhance procedure and maintenance. Predictive analytics can recognize potential issues prior to they cause failings, allowing for favorable maintenance that declines downtime and prolongs the life span of the turbine. Expert system formulas can check out substantial amounts of info to recognize patterns and boost control methods, better boosting efficiency. Enhancing turbine layout for optimal efficiency is a complex and lively procedure that needs a natural method, considering whatever from wind resistant layout and product choice to handle systems and digital adaptation. By leveraging ingenious modern technologies and layout principles, turbine designers can produce systems that transform power sources right into power with unparalleled efficiency, including in an additional lasting and trusted power future. Whether in the context of gas turbines driving business applications or wind turbines capitalizing on renewable resource, the mission of maximum efficiency remains to be a crucial unbiased that drives innovation and growth in the location.

Turbine efficiency is impacted by factors such as blade design, fuel quality, operating conditions, and maintenance practices.

Turbine efficiency can be optimized through regular maintenance, performance monitoring, upgrading components, and using advanced control systems.

Predictive maintenance helps identify potential issues before they affect efficiency, reducing downtime and improving overall turbine performance.

Blade design is crucial as it directly affects the aerodynamic performance of the turbine, influencing energy conversion and efficiency.

Optimizing turbine efficiency leads to reduced fuel consumption, lower operational costs, increased power output, and enhanced reliability.