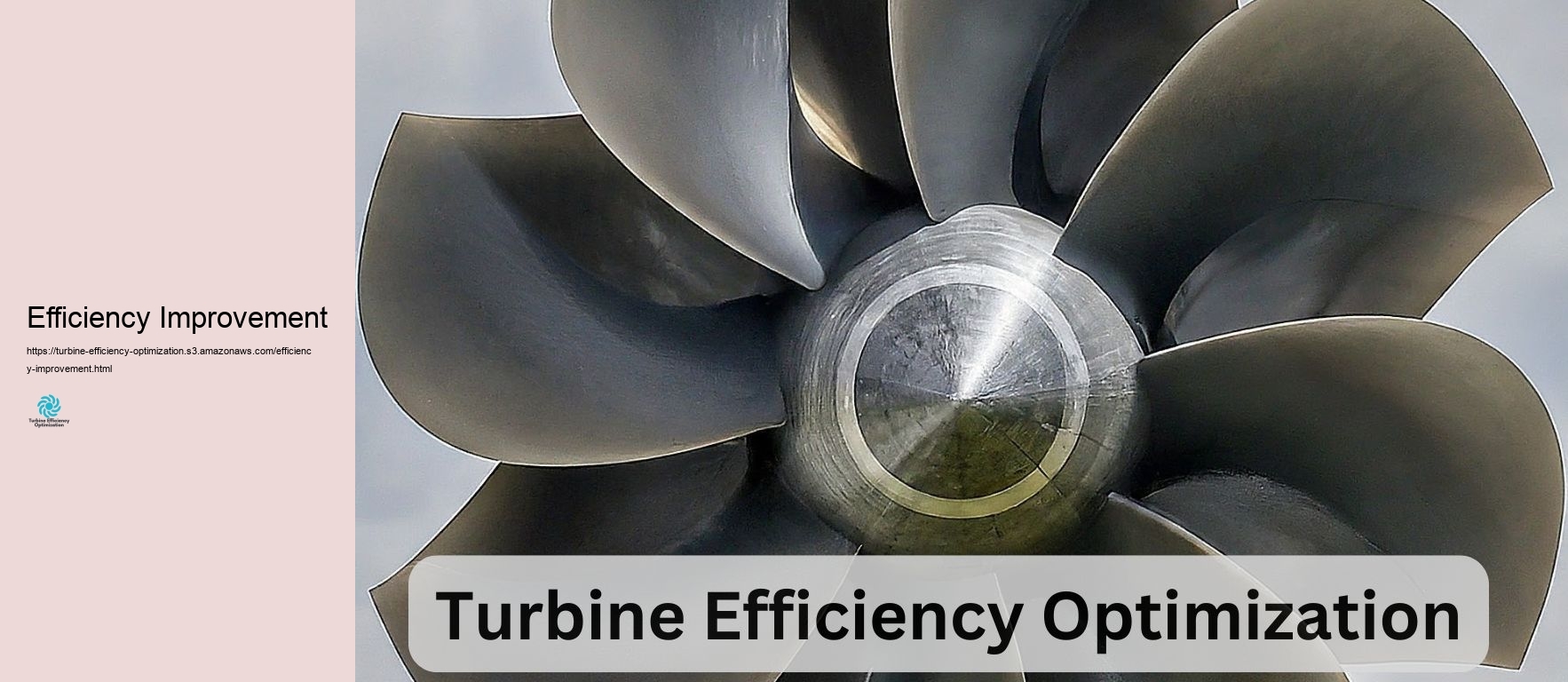

Turbine efficiency is a vital principle in the area of energy manufacturing and mechanical design. It describes the capability of a turbine to transform the power of a relocating fluid (such as water, vapor, or gas) into valuable mechanical work. Comprehending the concepts of turbine efficiency is essential for designers, power experts, and any person associated with the design, treatment, or maintenance of power generation systems. At its core, turbine efficiency is a measure of specifically how efficiently a turbine can remove energy from the liquid travelling with it. This efficiency is typically shared as a portion, with greater percents recommending far better efficiency. In an outstanding globe, a turbine would certainly have the capability to transform 100% of the fluid power right into mechanical job. However, actually, numerous variables add to power losses, leading to effectiveness that are always much less than 100 %. Among the main variables influencing turbine efficiency is the design of the turbine itself. The shape, dimension, and strategy of the turbine blades play a crucial responsibility in figuring out '' exactly how effectively the liquid power can be made use of. Modern turbine layouts generally consist of advanced wind resistant or hydrodynamic concepts to optimize the flow of liquid with the turbine, lowering losses and making ideal use of power extraction. The kind of fluid made use of in the turbine likewise substantially effects its efficiency. Heavy steam turbines, for instance, are often utilized in thermal power plants and have various efficiency aspects to think about contrasted to hydroelectric generators or wind wind turbines. The residential properties of the liquid, such as its thickness, temperature degree, and stress, all impact just how properly it can transfer energy to the turbine blades. An extra crucial facet of turbine efficiency is the principle of thermodynamic cycles. In countless power generation systems, wind turbines come from a larger thermodynamic cycle, such as the Rankine cycle in hefty vapor nuclear power plant or the Brayton cycle in gas generators. The basic efficiency of the system depends not just on the turbine's efficiency however on precisely how well it includes with the other elements of the cycle, such as central heating boilers, condensers, and compressors. The operating problems of the turbine furthermore play a significant feature in its efficiency. Facets such as the inlet temperature and stress of the fluid, the rotational rate of the turbine, and the lots on the turbine can all influence its efficiency. Generators are typically developed to operate most properly at specific conditions, referred to as the style factor. Running a turbine much from its layout factor can bring about lowered efficiency. Losses within the turbine system add to decreased efficiency. These losses can take place in numerous kinds, such as rubbing losses in bearings and seals, wind resistant losses as a result of turbulence and separation of circulation, and leakage losses where liquid bypasses the turbine blades without doing useful work. Minimizing these losses with cautious design and maintenance is essential for maximizing turbine efficiency. The idea of isentropic efficiency is commonly used when discussing turbine performance. This contrasts the real task end result of the turbine to the optimum work result that would certainly be achieved if the procedure were fairly simple to take care of and adiabatic (no cozy transfer). The isentropic efficiency offers a step of how close the turbine entails excellent efficiency and is a beneficial gadget for contrasting various turbine designs or operating problems. Item choice is another essential element to think about in turbine efficiency. The materials utilized for turbine blades and various other parts need to hold up against warms, tension, and stress and anxieties while preserving their shape and efficiency. Advanced items and treatments can boost turbine efficiency by allowing higher operating temperature level degrees, minimizing damage, and decreasing thermal losses. The range of the turbine can similarly impact its efficiency. Generally, bigger generators commonly have a tendency to be additional efficient than smaller sized ones as an outcome of reduced loved one surface and lower symmetrical losses. Efficiency Improvement Nonetheless, this require to be stabilized versus numerous other facets such as expense, capability, and certain application needs. Power output Maintenance and functional techniques substantially influence turbine efficiency with time. Regular upkeep, including cleaning up, examination, and replacement of made use of components, is needed for maintaining maximum performance. Furthermore, suitable operational procedures, such as progressive start-up and closure procedures and adherence to suggested running criteria, can aid safeguard turbine efficiency and broaden its life-span. Advancements in advancement continue to press the boundaries of turbine efficiency. Innovations such as 3D printing for intricate blade geometries, progressed picking up units and control systems for real-time optimization, and crossbreed formats that integrate different turbine kinds are all adding to improvements in efficiency. Environmental factors likewise contribute in turbine efficiency, specifically for wind and hydroelectric wind generators. For wind generators, facets such as wind rate, directions, and disruption influence their performance. In a similar means, for hydroelectric wind generators, water blood circulation rates, head altitude, and seasonal variations in water timetable all effect efficiency. Understanding and making best use of turbine efficiency is not merely a technical challenge nevertheless similarly an economic and ecological crucial. Increased efficiency converts to much better gas usage, reduced discharges, and reduced functional costs. In an age of boosting power demand and growing environmental problems, making the most of turbine efficiency is crucial for lasting power generation. The basics of turbine efficiency incorporate a big variety of variables, from standard thermodynamic principles to sophisticated materials scientific study and control systems. Developers and energy

specialists require to consider all these aspects to style, run, and maintain generators that obtain the biggest feasible efficiency. As modern innovation remains to development and our understanding of liquid qualities and energy conversion expands, we can expect additional enhancements in turbine efficiency, contributing to a lot more lasting and reliable energy manufacturing systems worldwide.

Method variables influencing turbine performance encompass a series of technical, environmental, and functional elements to consider that jointly determine the efficiency and effectiveness of both gas and wind generators. These aspects are vital in boosting the efficiency of wind turbines, which are essential in power generation, whether using changing kinetic wind energy right into electrical energy or utilizing the thermal power from gas combustion in gas generators. For gas wind generators, among among one of the most significant elements affecting efficiency is the ambient air temperature and website elevation. Gas turbines are air-breathing engines, meaning that the thickness and mass flow of the air intake directly impact their efficiency. Greater ambient temperature level degrees minimize air density, creating decreased mass flow and, subsequently, reduced power end result. In a similar way, greater altitudes cause lower air pressure, extra decreasing air density and influencing turbine efficiency. Consequently, comprehending and minimizing the impacts of these environmental troubles through design aspects to think about or functional modifications is vital for keeping optimal efficiency. Moisture is an additional eco-friendly variable that impacts gas turbine efficiency. Humid air is much less dense than completely dry air, which can minimize the mass circulation rate through the turbine and decrease power result. This variable is specifically appropriate in areas with high moisture degrees, where the efficiency of gas generators can be jeopardized. To battle these results, some generators are provided with with inlet air cooling systems, such as evaporative coolers or chillers, to enhance air thickness and improve performance. The kind and top quality of gas used in gas wind turbines furthermore play a critical duty in figuring out efficiency. Various gas have differing calorific worths, compositions, and burning attributes, each of which impact the thermal efficiency and power result of the turbine. Making sure that the gas satisfies particular top quality requirements and is compatible with the turbine's layout is essential for accomplishing optimal efficiency. Furthermore, using cutting-edge fuel heating systems can boost the combined cycle efficiency by making best use of the power material of the gas. Mechanical losses, such as massaging between transferring aspects like bearings and seals, can likewise influence turbine efficiency. These losses are generally lowered throughout the style phase through precision style and utilizing excellent items. Typical maintenance is essential to ensure that these aspects stay in great problem, thus minimizing mechanical losses and preserving efficiency. In the context of wind generators, wind speed and guidelines are the most vital elements affecting performance. Wind wind turbines transform the kinetic power of the wind right into electric power, and the amount of power captured is right symmetrical to the wind price. Likewise little boosts in wind rate can cause substantial gains in power result. Subsequently, choosing sites with constant and strong wind problems is essential for making the most of turbine efficiency. The placement of the turbine about the wind directions additionally influences efficiency, requiring robust yaw control systems to maintain optimal placement. Air density and temperature level likewise impact wind turbine efficiency, comparable to gas generators. Greater air thickness raises the mass circulation price using the turbine, boosting power outcome. On the other hand, greater temperatures can trigger thermal growth of materials, possibly influencing the efficiency of the generator and numerous other electrical aspects. Bookkeeping for these variations with style and operational techniques is necessary for making the most of efficiency. Turbulence and wake results are added variables that can impact wind turbine efficiency. Disruption explains the disorderly changes in wind rate and guidelines, which can trigger vibrations and tension on turbine parts, possibly produce tiredness and noise. Wake impacts happen when the wind rate and instructions are customized by the presence of upstream generators, affecting the performance of downstream devices in a wind cattle ranch. To reduce these impacts, mindful prep work of turbine style and spacing, in addition to cutting-edge control approaches, are called for. Control and optimization techniques are essential for both gas and wind generators to accomplish optimal efficiency. These techniques involve making use of innovative solutions and control systems to manage various operational requirements, such as blade pitch, blades rate, and generator torque. By continuously inspecting and changing these standards based upon real-time data, wind turbines can run a great deal more successfully and accurately, making ideal use of power outcome and reducing wear and tear. Ultimately, environmental and social results are extremely important factors to consider in turbine efficiency. For wind generators, facets such as land use, wild animals communications, and sound levels can influence public approval and regulative conformity. For gas generators, exhausts and source consumption are vital ecological issues. Addressing these influences with lasting techniques and stakeholder interaction is crucial for the lasting functionality of turbine tasks. The performance of turbines, whether gas or wind, is influenced by a detailed interplay of ecological, technical, and functional aspects. By recognizing and maximizing these variables, chauffeurs can boost efficiency, dependability, and sustainability, making certain that wind turbines remain to play an important function in the worldwide power landscape. Whether with progressed control systems, tactical site option, or innovative style alternatives, the pursuit of optimal turbine efficiency is a dynamic and constant procedure that demands constant adjustment and improvement.

Boost turbine performance and efficiency with advanced optimization techniques! Discover the latest strategies in design, materials, and technology to maximize energy output and minimize losses. Stay ahead in the evolving landscape of power generation.https://t.co/pZr0jaoH1i

— Turbine Training And Operation (@turbinetraine) August 25, 2024

Enhancing turbine efficiency is a crucial goal in various fields, consisting of power generation, aerospace, and production, as it right affects efficiency, cost-effectiveness, and environmental sustainability. Advanced methods for turbine efficiency renovation focus on improving layout, products, and useful methods to make finest use power result while reducing losses. Below, we uncover a number of sophisticated approaches that are transforming turbine modern technology and pressing the limits of efficiency. Among the most effective techniques to improve turbine efficiency is through wind resistant optimization. This entails fine-tuning the layout of turbine blades to lower drag and boost lift, for that reason boosting the conversion of kinetic power from wind or hefty steam into power. Computational fluid features (CFD) simulations play a crucial function in this process, making it possible for engineers to design air flow patterns and establish areas for remodelling. Advanced blade formats, such as those with twisted or conical forms, can substantially enhance aerodynamic performance. Mechanical engineering Furthermore, incorporating energetic flow control innovations, such as limitation layer suction or blowing, can in addition decrease wind immune losses and enhance efficiency. The development of sophisticated products is an additional essential take into consideration boosting turbine efficiency. High-performance items, such as superalloys and ceramic matrix compounds, deal costs toughness, heat resistance, and deterioration resistance, allowing wind turbines to run at greater temperatures and tension. This is specifically critical in gas wind generators, where boosted running temperature level levels can cause greater thermal efficiency. Furthermore, utilizing light-weight materials, such as carbon fiber compounds, can minimize the basic weight of turbine components, reducing inertia and boosting feedback times. Developments in additive making, or 3D printing, similarly license the manufacturing of complicated, boosted geometries that were formerly unattainable, extra enhancing item efficiency. Trustworthy cooling down is essential for maintaining turbine efficiency and expanding part life-span. Advanced cooling down methods, such as transpiration cooling and film cooling, are being created to handle the high thermal lots experienced by turbine blades and various other elements. Transpiration cooling involves the passage of a cooling fluid with a porous material, offering uniform a/c throughout the surface area. Movie cooling, on the other hand, requires the shot of a slim layer of coolant over the surface area of the component, creating a protective barrier versus cozy gases. These approaches assistance preserve maximum operating temperature level degrees, minimize thermal tension, and stop item deterioration, eventually boosting turbine efficiency. The combination of sophisticated control systems and digital modern technologies is transforming turbine efficiency. Modern control systems use real-time information from sensing devices and sophisticated algorithms to maximize turbine operation dynamically. This includes readjusting blade pitch, rotational rate, and different other criteria to readjust to changing environmental issues and load needs. Digital doubles, which are online reproductions of physical generators, allow constant tracking and anticipating maintenance, permitting operators to recognize feasible issues prior to they cause significant efficiency losses. Expert system and expert system are likewise being leveraged to assess big quantities of useful information, supplying understandings that drive furthermore efficiency renovations. Including crossbreed systems and renewable resource resources can improve overall turbine efficiency and sustainability. For example, incorporating wind wind turbines with solar panels or power storage systems can provide an additional stable and reputable power end result, reducing dependancy on nonrenewable gas sources. When it concerns gas wind turbines, incorporating with sustainable gas, such as hydrogen or biofuels, can minimize carbon exhausts while maintaining high efficiency. Moreover, crossbreed systems that incorporate various sorts of generators, such as wind and hydro, can maximize power capture and use, even more improving efficiency. Typical upkeep and security are vital for sustaining turbine efficiency with time. Advanced evaluation devices and methods, such as vibration analysis and thermography, enable early detection of deterioration, misalignments, and various other issues that can influence efficiency. Performing an aggressive maintenance method, continual by preparing for analytics, can lower downtime and expand the functional life span of turbine components. Remote surveillance systems enable regular oversight of turbine efficiency, permitting prompt treatments and changes to maintain optimal efficiency. Enhancing turbine efficiency is not just a technological problem yet also an environmental and financial important. A lot more trustworthy turbines consume much less gas and produce fewer exhausts, adding to a reduction in greenhouse gases and numerous other pollutants. This align with around the world efforts to manage climate modification and shift to cleaner power sources. Monetarily, greater efficiency converts to lower useful expenses and enhanced competition, as drivers can create much more power with the exact very same resources. Therefore, financial investment in ingenious turbine technologies is a crucial priority for both sector leaders and policymakers. Looking ahead of time, a number of arising fads and technologies hold promise for added boosting turbine efficiency. The improvement of sensible products with adaptive buildings might result in self-healing components that maintain efficiency under extreme problems. Developments in nanotechnology may result in layers that minimize friction and put on, further extending aspect life. Furthermore, the expedition of unique turbine designs, such as bladeless or vertical-axis wind turbines, could offer brand-new pathways for efficiency gains. As r & & d campaigns continue, the possibility for growths in turbine advancement remains considerable, driving development in the direction of an extra lasting and efficient power future. Enhancing turbine efficiency is a diverse taking on that calls for a mix of ingenious style, items, and functional approaches. By leveraging innovative modern technologies and ingenious approaches, the industry can accomplish substantial gains in efficiency, sustainability, and cost-effectiveness. As the demand for cleaner and a lot even more efficient power services grows, the search of turbine efficiency will certainly remain a crucial emphasis for scientists, developers, and policymakers alike, creating the future of energy generation and usage.

Maintaining perfect turbine operation is vital for assuring effective power manufacturing, lessening downtime, and extending the life-span of these complex devices. Reputable maintenance approaches are essential for nuclear power plant, wind cattle ranches, and industrial centers that trust generators for their treatments. By accomplishing a thorough maintenance strategy, chauffeurs can make the most of efficiency, reduction rates, and boost general stability. Among the standard maintenance approaches for maximum turbine procedure is the execution of a long lasting anticipating upkeep program. This technique utilizes ingenious security technologies and details analytics to expect prospective issues prior to they result in failures or considerable efficiency deterioration. Sensors and watching on systems are mounted throughout the turbine to build up real-time details on various specifications such as resonance, temperature level, tension, and oil problem. This details is afterwards reviewed taking advantage of sophisticated algorithms and machine learning methods to figure out patterns and irregularities that might program creating concerns. Anticipating maintenance enables drivers to established upkeep tasks based upon the actual problem of the tools rather than depending solely on dealt with time durations. This approach assists avoid unforeseen failures, reductions unneeded upkeep, and takes full advantage of making use of sources. By attending to issues early, chauffeurs can stay clear of extra extensive and pricey correctings down the line, unavoidably increasing the turbine's complete dependability and efficiency. Routine examinations and condition analyses develop another essential component of reliable turbine maintenance strategies. These inspections has to be performed at fixed periods and include both visual assessments and non-destructive evaluating strategies. Visual exams can recognize obvious indicators of wear, damages, or rust, while non-destructive testing techniques such as ultrasonic evaluating, magnetic bit assessment, and swirl existing screening can uncover surprise problems or internal problems in essential elements. Throughout these assessments, details focus ought to be paid to high-stress locations and components recognized to be vulnerable to placed on or failing. This consists of turbine blades, bearings, transmissions, and seals. By establishing and dealing with possible problems early, vehicle drivers can protect against little troubles from magnifying right into major failings that could cause extended downtime and significant repair work solution rates. Applying a thorough lubrication management program is essential for keeping ideal turbine treatment. Appropriate lubrication is essential for decreasing friction, dissipating warm, and protecting components from wear and degeneration. This program should include regular oil evaluation to check the problem of lubes and place any kind of indicators of contamination or degeneration. Oil samples should certainly be taken and checked out at typical intervals to track adjustments in viscosity, level of acidity, and the visibility of wear bits or pollutants. Based on the outcomes of oil assessment, operators can determine when oil alterations or filtration are required, ensuring that the turbine always operates with clean, state-of-the-art lubricating substances. Additionally, the lubrication program should certainly contain proper storage and managing therapies for lubricating materials to quit contamination and maintain their performance. Vibration checking and analysis is an extra important component of turbine maintenance approaches. Too much vibration can recommend numerous troubles, including imbalance, inequality, birth wear, or loosened elements. By continually examining resonance levels and patterns, drivers can discover producing issues early and take rehabilitative activity prior to they reason a great deal even more severe problems or failing. Advanced resonance analysis techniques, such as scary analysis and orbit stories, can offer detailed understandings right into the nature and area of possible concerns. This information permits maintenance groups to concentrate their efforts on specific components or places of fear, improving the efficiency and performance of upkeep jobs. Thermal imaging is an additional useful device in the maintenance toolbox for perfect turbine treatment. Regular thermal assessments can uncover places or abnormal temperature degree patterns that could recommend concerns such as insulation break down, electrical blunders, or birthing problems. By figuring out these problems early, operators can prevent prospective failings and make the most of the turbine's thermal efficiency. Carrying out a durable spare elements management system is vital for minimizing downtime and guaranteeing quick comments to upkeep needs. This system ought to include a comprehensive supply of important parts, with clear standards for supply degrees, reordering procedures, and storage space issues. By preserving a suitable supply of important extra elements on-hand, drivers can considerably lower the moment needed to surface fixing services and return the turbine to remedy. Training and skill growth for upkeep personnel is a crucial however usually ignored element of reputable turbine maintenance methods. Recurring training programs require to be applied to make sure that maintenance group are up-to-date with the most current innovations, finest methods, and safety and security and protection therapies. This consists of both technical abilities connected with turbine upkeep and soft abilities such as problem-solving and communication. Routine efficiency screening and efficiency tracking are crucial for keeping ideal turbine procedure. These evaluations can aid recognize any deterioration in performance slowly and permit operators to take corrective activity to recover the turbine to peak efficiency. Efficiency testing needs to contain measurements of power outcome, gas usage, and tires levels'., in addition to analyses of private element effectiveness. Applying an electronic upkeep keeping an eye on system (CMMS) can considerably boost the efficiency of turbine maintenance approaches. A CMMS can assist improve upkeep organizing, track work orders, look after supply, and offer important data for analysis and decision-making. By streamlining upkeep information and automating lots of normal jobs, a CMMS can boost basic upkeep efficiency and support make sure that no important maintenance jobs are overlooked.

Cutting-edge modern technologies in turbine efficiency optimization are transforming the landscape of power production, supplying brand-new means to increase efficiency, minimize ecological influence, and enhance the sustainability of power generation systems. As around the world demand for trusted and clean power remedies remains to climb, developments in turbine innovation are coming to be significantly crucial. These developments cover a selection of areas, including products scientific study, electronic contemporary technology, burning treatments, and aerodynamic style, each including in the complete efficiency and efficiency of generators used in different applications, from power plants to wind ranches. Among one of the most significant developments in turbine efficiency optimization is making use of innovative items and coverings. Wind wind turbines operate under severe troubles, with high temperatures and stress that traditional products can not sustain without derogatory. Developments in items scientific study have resulted in the advancement of superalloys, specifically those based upon nickel, which preserve their toughness and security at elevated temperature level degrees. These products lengthen the life-span of turbine aspects and license them to operate at better efficiencies. Furthermore, thermal challenge coverings (TBCs), such as sophisticated ceramic compounds, are related to turbine parts to secure them from cozy and enhance their durability. These layers job as insulators, maintaining the steel elements cooler and enhancing their efficiency under harsh issues. Additive manufacturing, or 3D printing, is changing the manufacturing and upkeep of turbine parts. This modern-day technology permits the manufacturing of center, high-precision components that are challenging or tough to manufacture utilizing standard techniques. Additive making makes it possible for quick prototyping, permitting engineers to rapidly develop, assessment, and enhance turbine elements, enhancing the development process. Efficiency metrics The ability to produce components as needed declines the demand for big inventories of extra parts and lowers downtime, as replacement parts can be made and mounted quickly. In addition, additive manufacturing aids with the making of components with sophisticated geometries that enhance airflow and cooling within the turbine, further improving efficiency and reducing thermal anxiety. The combination of digital technologies into turbine treatments has really opened up brand-new possibilities for efficiency optimization. Digital twins, digital replicas of physical wind generators, allow chauffeurs to mimic and watch on turbine efficiency in real-time. By analyzing details from sensors and digital increases, preparing for maintenance algorithms can projection when a turbine component is likely to fall short, allowing maintenance to be organized at optimal times. This favorable approach reductions downtime and maintenance rates while making sure that wind turbines run at peak efficiency levels. Predictive maintenance not only expands the life expectancy of turbine components however also takes full advantage of efficiency by avoiding unexpected failings and improving functional specifications. Developments in melting modern innovation are crucial to boosting turbine efficiency and decreasing ecological influence. Conventional burning procedures in generators create nitrogen oxides (NOx), hazardous toxins that add to air pollution. Designers have developed low-NOx combustors that reduction NOx growth by making best use of the burning procedure. These innovative combustors use methods such as lean-burn strategies and boosted fuel-air mixing to decline tires without endangering performance. As the globe changes to cleaner power sources, hydrogen is becoming an appealing gas for wind turbines. Hydrogen burning produces just water vapor as a result, getting rid of CO2 discharges. Technologies in hydrogen burning modern-day innovation are permitting generators to operate effectively with this tidy gas, contributing to an additional sustainable energy landscape. The wind resistant design of turbine blades plays a vital role in determining the efficiency and efficiency of both gas and wind wind turbines. Advances in the guidelines of the rules of aerodynamics and blade design have really created considerable improvements in turbine efficiency. Developers usage computational fluid characteristics (CFD) and 3D printing to create aerodynamically optimized blade formats that boost the flow of air and gases with the turbine, decreasing power losses and increasing general efficiency. In wind generators, variable pitch and twist styles make it possible for blades to adjust dynamically to altering wind conditions, maximizing efficiency and reducing mechanical anxiousness. These modern technologies in blade format enhance the efficiency and life-span of wind turbines, making them a lot even more competitive with standard power sources. The integration of renewable resource resources is an extra area of technology targeted at enhancing turbine efficiency and sustainability. Crossbreed systems that incorporate wind turbines with renewable energy resources, such as solar or wind, can enhance overall power production and lower dependence on nonrenewable fuel sources. These systems make the most of the equivalent nature of numerous energy sources to offer a much more protected and trustworthy power supply. As an example, incorporating wind generators with photovoltaic or pv panels can counter periods of lowered wind with solar power manufacturing, ensuring a continuous power supply. This assimilation not just increases the efficiency of energy systems yet also maintains the change to an additional lasting power future. Ingenious advancements in turbine efficiency optimization are driving significant improvements in the power area. By leveraging developments in materials science, electronic technology, shedding procedures, and wind resistant layout, generators are becoming a whole lot more reliable, trustworthy, and environment-friendly. These growths are vital for pleasing the increasing demand for tidy and effective power treatments and play a crucial role in the international modification to lasting power systems. As {research and development proceed, the possibility for better renovations in turbine contemporary innovation remains to be substantial, assuring a future of likewise better efficiency and sustainability in energy producing.

Making the most of turbine layout for ideal efficiency is a diverse endeavor that entails a deep understanding of wind resistant principles, item clinical research study, thermodynamics, and advanced design methods. Whether handling gas generators utilized in nuclear power plant and airplane or wind wind turbines utilizing renewable resource, the goal is to change power resources into mechanical or electrical power with the greatest viable efficiency. Completing this needs an extensive technique that takes into account every element of the turbine's format, from the type and products of the blades to the arrangement of the whole system. For gas generators, efficiency optimization begins with the layout of the compressor and turbine blades. These blades have to be diligently engineered to endure heats and stress while decreasing wind resistant drag. Advanced computational liquid characteristics (CFD) simulations are made use of to design air flow over the blades, allowing engineers to improve their shape for perfect performance. Using high-performance products, such as cutting-edge alloys and ceramics, permits blades to run at higher temperatures, which is essential for enhancing thermal efficiency. Additionally, incorporating cooling down contemporary technologies, such as film cooling or transpiration cooling down, assists keep blade sincerity under extreme conditions, much more improving efficiency. The shedding chamber is one more vital component in gas turbine format. It ought to be developed to make sure total and dependable combustion of the gas, lessening tires and making best use of power result. Developments such as lean-burn shedding innovation, which decreases the amount of excess air in the shedding process, can considerably enhance efficiency and minimize nitrogen oxide exhausts. In addition, the adaptation of sophisticated control systems permits precise legislation of gas and air combinations, maximizing melting problems in real-time based upon running criteria. In the context of wind turbines, optimizing design for maximum efficiency includes a concentrate on the rotor blades, which are in charge of catching the kinetic power of the wind. The aerodynamic form of the blades is exceptionally important; they need to be made to maximize lift while reducing drag. This commonly involves making use of airfoil shapes that are optimized for information wind problems. Engineers use wind tunnel screening and CFD simulations to modify blade styles, ensuring they execute effectively throughout a collection of wind rates. In addition, making use of light-weight composite items, such as carbon fiber or fiberglass, minimizes the basic weight of the blades, allowing them to respond much more dynamically to modifications in wind problems and improving general efficiency. The elevation and positioning of wind generators are likewise essential consider enhancing efficiency. Efficiency Improvement Taller towers permit generators to gain access to higher wind rates, which are usually more continuous and effective. Site option, as a result, consists of careful examination of wind patterns and topography to make sure generators are located where they can record one of the most power. In wind ranches, the layout of generators must be tactically desired to lower wake effects, where the disturbance created by one turbine influences the efficiency of others downwind. By maximizing the spacing and alignment of generators, power capture can be maximized across the entire ranch. Control systems play an essential duty in improving turbine efficiency, both for gas and wind generators. For gas wind turbines, proceeded control systems keep track of and adjust specifications such as gas circulation, air intake, and exhaust temperature levels to protect optimal running conditions. These systems can respond to adjustments popular and environmental conditions, making sure that the turbine runs at peak efficiency in all times. In wind wind turbines, control systems modification the pitch of the blades and the yaw of the nacelle to straighten with changing wind instructions and rates, making best use energy capture while reducing mechanical anxiousness. Power storage room and hybrid systems are emerging as important aspects to take into consideration in turbine layout, specifically for renewable resource applications. Incorporating power storage space choices, such as batteries or flywheels, can assist ravel the irregularity of wind power, conserving excess power throughout durations of high production and releasing it when demand is higher. Crossbreed systems that include wind generators with other energy resources, such as solar panels or gas turbines, can supply a lot more consistent power output and improve overall efficiency. The combination of digital contemporary technologies and data analytics is changing turbine format and procedure. Using sensors and IoT gadgets enables real-time tracking of turbine efficiency, providing valuable data that can be utilized to maximize operation and maintenance. Expecting analytics can determine prospective problems prior to they cause failures, allowing proactive maintenance that declines downtime and extends the life expectancy of the turbine. Expert system algorithms can analyze substantial quantities of details to identify patterns and enhance control techniques, even more boosting efficiency. Optimizing turbine design for optimal efficiency is a center and vivid procedure that ask for a different strategy, taking into consideration whatever from aerodynamic layout and product alternative to regulate systems and electronic assimilation. By leveraging advanced innovations and design concepts, turbine designers can create systems that convert energy resources right into power with unequaled efficiency, including in a much more lasting and reputable power future. Whether in the context of gas wind generators driving industrial applications or wind wind turbines making the most of renewable resource, the pursuit of optimum efficiency stays a vital unbiased that drives growth and development in the area.

Turbine efficiency is impacted by factors such as blade design, fuel quality, operating conditions, and maintenance practices.

Turbine efficiency can be optimized through regular maintenance, performance monitoring, upgrading components, and using advanced control systems.

Predictive maintenance helps identify potential issues before they affect efficiency, reducing downtime and improving overall turbine performance.

Blade design is crucial as it directly affects the aerodynamic performance of the turbine, influencing energy conversion and efficiency.

Optimizing turbine efficiency leads to reduced fuel consumption, lower operational costs, increased power output, and enhanced reliability.