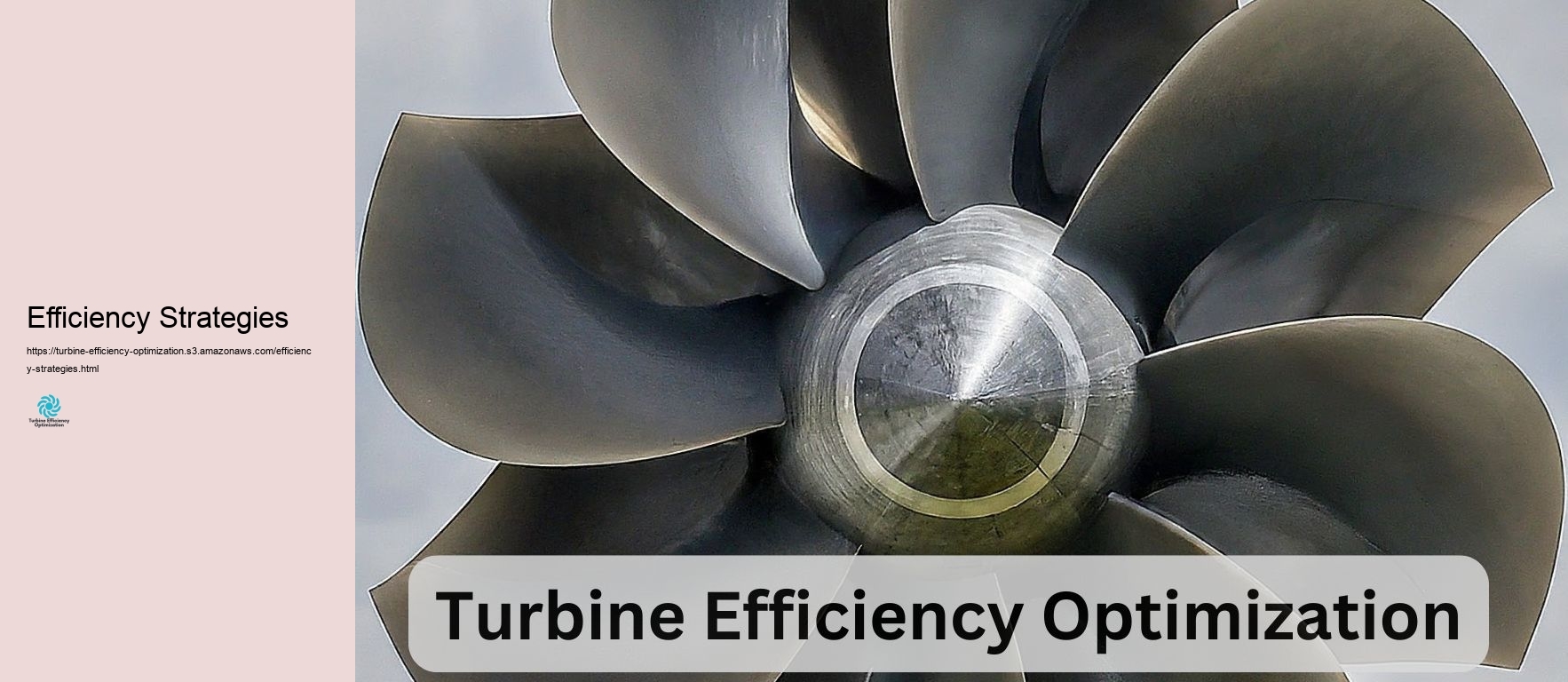

Turbine efficiency is a vital concept in the location of power making and mechanical layout. It describes the capability of a turbine to change the power of a moving fluid (such as water, vapor, or gas) right into beneficial mechanical work. Comprehending the principles of turbine efficiency is essential for designers, energy experts, and anybody related to the design, procedure, or maintenance of power generation systems. At its core, turbine efficiency is a procedure of specifically how effectively a turbine can extract power from the fluid undergoing it. This efficiency is normally shared as a percent, with higher parts revealing better performance. In an optimal globe, a turbine would definitely have the ability to transform 100% of the fluid power right into mechanical job. However, actually, many aspects include in energy losses, leading to efficiencies that are constantly a lot less than 100 %. Among the crucial variables influencing turbine efficiency is the style of the turbine itself. The kind, dimension, and arrangement of the turbine blades play a necessary role in determining '' just how effectively the fluid power can be harnessed. Modern turbine designs typically incorporate sophisticated wind immune or hydrodynamic concepts to maximize the circulation of liquid using the turbine, decreasing losses and making finest use of energy removal. The kind of liquid used in the turbine furthermore drastically affects its efficiency. Vapor generators, as an instance, are typically made use of in thermal power plants and have different efficiency elements to think about contrasted to hydroelectric wind generators or wind generators. The properties of the liquid, such as its thickness, temperature level, and stress, all affect simply exactly how efficiently it can transfer power to the turbine blades. Efficiency Strategies An extra essential facet of turbine efficiency is the principle of thermodynamic cycles. In lots of power generation systems, generators become part of a bigger thermodynamic cycle, such as the Rankine cycle in heavy vapor nuclear reactor or the Brayton cycle in gas generators. The general efficiency of the system depends not simply on the turbine's efficiency however on simply exactly how well it incorporates with the different other elements of the cycle, such as boilers, condensers, and compressors. The operating problems of the turbine furthermore play a considerable obligation in its efficiency. Factors such as the inlet temperature and tension of the fluid, the rotational rate of the turbine, and the loads on the turbine can all influence its efficiency. Generators are typically created to operate most successfully at certain conditions, called the design point. Running a turbine far from its style point can cause minimized efficiency. Losses within the turbine system contribute to decreased efficiency. These losses can occur in many kinds, such as scrubing losses in bearings and seals, wind resistant losses as an outcome of disruption and separation of flow, and leakage losses where liquid bypasses the turbine blades without doing handy job. Reducing these losses with cautious style and maintenance is crucial for making finest use turbine efficiency. The principle of isentropic efficiency is usually made use of when talking about turbine efficiency. This contrasts the actual job outcome of the turbine to the excellent job result that would be achieved if the procedure were reversible and adiabatic (no warmth transfer). The isentropic efficiency offers a step of just how close the turbine concerns ideal efficiency and is a helpful gadget for contrasting various turbine designs or running issues. Product option is another vital aspect to consider in turbine efficiency. The materials made use of for turbine blades and numerous other parts needs to stand up versus heats, stress and anxiety, and concerns while keeping their form and efficiency. Advanced products and finishes can enhance turbine efficiency by allowing greater running temperature levels, lowering damages, and reducing thermal losses. The scale of the turbine can furthermore influence its efficiency. Usually, larger turbines have a tendency to be more efficient than smaller sized ones due to reduced loved one surface area and lower proportional losses. However, this needs to be well balanced against numerous other variables such as cost, capability, and specific application demands. Maintenance and operational methods considerably influence turbine efficiency with time. Efficiency Strategies Normal maintenance, consisting of cleansing, assessment, and substitute of used parts, is important for maintaining optimal efficiency. Additionally, proper functional therapies, such as progressive startup and closure processes and adherence to recommended operating specs, can help maintain turbine efficiency and extend its life-span. Breakthroughs in advancement remain to press the limits of turbine efficiency. Performance tuning Improvements such as 3D printing for challenging blade geometries, proceeded sensing units and control systems for real-time optimization, and crossbreed styles that integrate various turbine kinds are all including in improvements in efficiency. Ecological facets additionally play a role in turbine efficiency, particularly for wind and hydroelectric generators. For wind generators, aspects such as wind speed, instructions, and disruption impact their efficiency. In a comparable means, for hydroelectric wind generators, water blood circulation rates, head elevation, and seasonal variations in water accessibility all result efficiency. Comprehending and maximizing turbine efficiency is not simply a technological difficulty yet likewise a monetary and ecological essential. Boosted efficiency converts to far better fuel application, minimized discharges, and minimized operational costs. In a period of elevating power demand and expanding ecological problems, maximizing turbine efficiency is vital for lasting power generation. The essentials of turbine efficiency consist of a large range of components, from standard thermodynamic principles to sophisticated materials clinical study and control systems. Engineers and power professionals have to take into consideration all these facets to style, run, and maintain turbines that acquire the highest possible efficiency. As technology continues to be to breakthrough and our understanding of liquid dynamics and energy conversion deepens, we can expect further renovations in turbine efficiency, adding to a lot more sustainable and efficient power producing systems worldwide.

Technique aspects affecting turbine efficiency include a range of technical, eco-friendly, and useful factors to take into consideration that jointly determine the efficiency and performance of both gas and wind generators. These variables are vital in making the most of the efficiency of generators, which are vital in power generation, whether through converting kinetic wind power right into electric power or making use of the thermal power from gas burning in gas wind turbines. For gas generators, amongst one of the most substantial factors influencing performance is the ambient air temperature degree and website elevation. Gas turbines are air-breathing engines, implying that the density and mass flow of the air intake directly influence their performance.

Boost turbine performance and efficiency with advanced optimization techniques! Discover the latest strategies in design, materials, and technology to maximize energy output and minimize losses. Stay ahead in the evolving landscape of power generation.https://t.co/pZr0jaoH1i

— Turbine Training And Operation (@turbinetraine) August 25, 2024

Enhancing turbine efficiency is a crucial objective in various industries, containing power generation, aerospace, and production, as it directly influences efficiency, cost-effectiveness, and eco-friendly sustainability. Advanced strategies for turbine efficiency enhancement concentrate on maximizing style, materials, and functional methods to maximize energy outcome while lessening losses. Right right here, we discover numerous advanced methods that are transforming turbine technology and pressing the borders of efficiency. Among the most reliable methods to boost turbine efficiency is with wind resistant optimization. This involves refining the style of turbine blades to minimize drag and boost lift, consequently enhancing the conversion of kinetic power from wind or heavy steam right into power. Computational liquid characteristics (CFD) simulations play a vital function in this procedure, permitting developers to layout air activity patterns and establish locations for improvement. Advanced blade styles, such as those with twisted or conical forms, can significantly enhance wind immune efficiency. Furthermore, including energetic flow control innovations, such as restriction layer suction or blowing, can much more decrease aerodynamic losses and boost efficiency. The development of cutting-edge products is another important factor in boosting turbine efficiency. High-performance items, such as superalloys and ceramic matrix substances, supply remarkable stamina, warmth resistance, and degeneration resistance, making it possible for wind turbines to run at higher temperatures and stress. This is specifically vital in gas generators, where enhanced running temperature levels can bring about better thermal efficiency. In addition, using light-weight products, such as carbon fiber compounds, can reduction the overall weight of turbine elements, minimizing inertia and improving activity times. Breakthroughs in additive making, or 3D printing, also make it possible for the growth of complicated, improved geometries that were previously unattainable, a lot more enhancing product efficiency. Trusted air conditioning is crucial for keeping turbine efficiency and lengthening component life-span. Advanced cooling techniques, such as transpiration cooling and film a/c, are being produced to take care of the high thermal bunches experienced by turbine blades and various other components. Transpiration cooling includes the flow of an air conditioning liquid via an absorptive material, giving consistent air conditioning throughout the surface. Power plant automation Movie cooling down, on the various other hand, entails the shot of a slim layer of coolant over the surface area of the aspect, generating a safety challenge versus hot gases. These approaches help preserve maximum running temperature level degrees, reduction thermal stress, and stop product degeneration, at some point enhancing turbine efficiency. The assimilation of innovative control systems and electronic modern innovations is changing turbine efficiency. Modern control systems use real-time info from picking up devices and innovative algorithms to optimize turbine procedure dynamically. This contains readjusting blade pitch, rotational price, and various other specs to adjust to modifying environmental problems and whole lots demands. Digital increases, which are online replicas of physical wind turbines, make it feasible for continuous keeping an eye on and anticipating upkeep, making it possible for drivers to determine possible issues before they bring about substantial efficiency losses. Artificial intelligence and expert system are likewise being leveraged to analyze considerable quantities of functional data, supplying insights that drive much more efficiency improvements. Incorporating crossbreed systems and renewable energy sources can improve general turbine efficiency and sustainability. As an example, including wind generators with photovoltaic or pv panels or power storage space systems can give a much more steady and relied on power outcome, decreasing dependence on nonrenewable fuel sources. When it comes to gas wind turbines, integrating with environment-friendly gas, such as hydrogen or biofuels, can decrease carbon tires while maintaining high efficiency. In addition, crossbreed systems that incorporate different sorts of wind turbines, such as wind and hydro, can enhance energy capture and usage, much better boosting efficiency. Routine upkeep and monitoring are essential for keeping turbine efficiency in time. Advanced diagnostic gadgets and techniques, such as resonance assessment and thermography, permit very early exploration of deterioration, misalignments, and various other issues that can influence performance. Using a hostile maintenance technique, supported by predictive analytics, can decline downtime and prolong the operational life expectancy of turbine components. Remote monitoring systems allow continual oversight of turbine efficiency, making it possible for punctual therapies and alterations to keep optimum efficiency. Enhancing turbine efficiency is not just a technical difficulty yet also an eco-friendly and financial important. Far more reliable generators take in much less gas and produce much less wears down, including in a reduction in greenhouse gases and other impurities. This lines up with worldwide efforts to fight climate adjustment and shift to cleaner power sources. Financially, higher efficiency converts to lower operational expenses and enhanced competition, as drivers can produce even more power with the precise very same resources. Thus, monetary investment in advanced turbine modern technologies is an important priority for both market leaders and policymakers. Looking in advance, a number of arising crazes and developments hold warranty for further boosting turbine efficiency. The improvement of sensible items with adaptable property or industrial residential or commercial properties can reason self-healing components that keep efficiency under extreme problems. Developments in nanotechnology might bring about finishings that minimize rubbing and use, additionally lengthening component life. Moreover, the expedition of unique turbine designs, such as bladeless or vertical-axis wind generators, can give new paths for efficiency gains. As research and development efforts continue, the capability for developments in turbine modern-day technology stays substantial, driving progression toward an additional lasting and efficient power future. Enhancing turbine efficiency is a varied endeavor that calls for a mix of ingenious design, items, and operational methods. By leveraging cutting-edge advancements and cutting-edge techniques, the market can achieve significant gains in efficiency, sustainability, and cost-effectiveness. As the demand for cleaner and a great deal even more efficient power solutions grows, the search of turbine efficiency will certainly remain a vital emphasis for scientists, developers, and policymakers alike, shaping the future of power generation and application.

Preserving optimal turbine treatment is vital for making certain efficient power making, decreasing downtime, and prolonging the life expectancy of these complex makers. Effective upkeep methods are required for power plants, wind ranches, and industrial facilities that count on generators for their operations. By carrying out a comprehensive maintenance technique, operators can maximize performance, minimize rates, and improve total integrity. Amongst the basic maintenance techniques for suitable turbine treatment is the execution of a durable anticipating maintenance program. This approach usages innovative tracking technologies and data analytics to expect feasible problems prior to they cause failures or considerable efficiency deterioration. Sensing units and watching on systems are set up throughout the turbine to collect real-time information on numerous specs such as resonance, temperature level, anxiety, and oil trouble. This information is after that checked out using ingenious formulas and artificial intelligence methods to identify patterns and abnormalities that might show developing issues. Predictive upkeep makes it possible for chauffeurs to organize upkeep activities based upon the real problem of the tools instead of relying entirely on set time durations. This method assists safeguard versus unanticipated malfunctions, decreases unnecessary maintenance, and improves using resources.

Ingenious contemporary technologies in turbine efficiency optimization are transforming the landscape of power manufacturing, providing brand-new methods to increase efficiency, decline environmental effect, and boost the sustainability of power generation systems. As global requirement for efficient and tidy power treatments stays to increase, developments in turbine modern innovation are winding up being significantly crucial. These modern technologies span a series of locations, containing materials scientific research, digital modern technology, combustion treatments, and wind immune layout, each adding to the overall efficiency and efficiency of generators utilized in different applications, from nuclear reactor to wind cattle ranches. One of one of the most significant developments in turbine efficiency optimization is using sophisticated products and finishes. Generators run under extreme conditions, with warms and stress that conventional products can not stand up versus without deteriorating. Technologies in materials science have really brought about the growth of superalloys, especially those based upon nickel, which keep their toughness and stability at raised temperatures. These items extend the life-span of turbine parts and enable them to operate at better efficiencies. Furthermore, thermal barrier finishes (TBCs), such as innovative ceramic compounds, are related to turbine components to safe and secure them from warm and boost their longevity. These layers feature as insulators, preserving the metal components cooler and boosting their efficiency under extreme problems. Additive manufacturing, or 3D printing, is revolutionizing the producing and maintenance of turbine components. This innovation enables the manufacturing of facility, high-precision components that are hard or difficult to make utilizing typical approaches. Additive manufacturing makes it possible for quick prototyping, enabling engineers to quickly layout, evaluation, and improve turbine parts, quickening the development treatment. The capability to create parts as needed declines the demand for huge supplies of extra elements and lowers downtime, as alternative elements can be made and mounted quickly. In addition, additive manufacturing helps with the making of components with intricate geometries that optimize air movement and air conditioning within the turbine, further enhancing efficiency and lowering thermal tension. The combination of digital technologies right into turbine operations has opened up new approaches for efficiency optimization. Digital doubles, digital reproductions of physical generators, permit drivers to simulate and screen turbine efficiency in real-time. By evaluating data from noticing devices and digital increases, preparing for maintenance solutions can forecast when a turbine aspect is probably to quit working, permitting upkeep to be set up at perfect times. This positive strategy reductions downtime and upkeep rates while ensuring that turbines operate at peak performance levels. Anticipating upkeep not simply expands the life span of turbine components yet furthermore optimizes efficiency by protecting versus unpredicted failures and optimizing practical specs. Innovations in shedding innovation are essential to improving turbine efficiency and reducing environmental influence. Typical burning processes in wind generators create nitrogen oxides (NOx), harmful toxins that add to air contamination. Developers have in fact created low-NOx combustors that reduce NOx growth by optimizing the melting procedure. These sophisticated combustors utilize methods such as lean-burn approaches and boosted fuel-air mixing to lower discharges without endangering efficiency. As the globe modifications to cleaner power resources, hydrogen is emerging as an attractive gas for generators. Hydrogen combustion develops just water vapor as a result, removing co2 exhausts. Dope in hydrogen combustion development are enabling generators to run successfully with this tidy gas, adding to a more sustainable power landscape. The wind immune style of turbine blades plays a vital function in determining the efficiency and performance of both gas and wind generators. Advancements in the guidelines of aerodynamics and blade style have caused substantial remodellings in turbine performance.

Enhancing turbine style for optimum efficiency is a complicated venture that includes a deep understanding of wind resistant concepts, product clinical research study, thermodynamics, and advanced engineering techniques. Whether looking after gas generators used in nuclear reactor and airplane or wind generators taking advantage of renewable resource, the objective is to transform power sources right into mechanical or electrical power with the best viable efficiency. Attaining this needs a thorough strategy that thinks about every element of the turbine's style, from the form and products of the blades to the arrangement of the whole system. For gas generators, efficiency optimization starts with the format of the compressor and turbine blades. These blades needs to be faithfully crafted to hold up against heats and stress while reducing wind resistant drag. Advanced computational fluid dynamics (CFD) simulations are made use of to layout air movement over the blades, enabling designers to boost their shape for perfect performance. Utilizing high-performance materials, such as innovative alloys and porcelains, makes it possible for blades to run at greater temperature levels, which is crucial for improving thermal efficiency. Moreover, integrating cooling down innovations, such as movie cooling or transpiration a/c, helps keep blade honesty under severe issues, additionally boosting efficiency. The shedding chamber is one more essential element in gas turbine format. It needs to be made to ensure full and reliable burning of the fuel, reducing discharges and maximizing power outcome. Developments such as lean-burn burning innovation, which lessens the quantity of excess air in the shedding procedure, can considerably increase efficiency and reduce nitrogen oxide exhausts. In addition, the assimilation of innovative control systems allows for exact guideline of gas and air blends, taking full advantage of melting problems in real-time based upon running standards. In the context of wind turbines, making the most of design for ideal efficiency entails a concentrate on the rotor blades, which are accountable for capturing the kinetic power of the wind. The wind resistant kind of the blades is important; they must be made to take full advantage of lift while lessening drag. This usually includes making use of airfoil shapes that are made the most of for specific wind problems. Engineers make use of wind passage evaluating and CFD simulations to tweak blade designs, guaranteeing they execute efficiently throughout a range of wind rates. In addition, the use of lightweight composite products, such as carbon fiber or fiberglass, declines the overall weight of the blades, making it possible for them to respond even more dynamically to adjustments in wind troubles and enhancing overall efficiency.

Turbine efficiency is impacted by factors such as blade design, fuel quality, operating conditions, and maintenance practices.

Turbine efficiency can be optimized through regular maintenance, performance monitoring, upgrading components, and using advanced control systems.

Predictive maintenance helps identify potential issues before they affect efficiency, reducing downtime and improving overall turbine performance.

Blade design is crucial as it directly affects the aerodynamic performance of the turbine, influencing energy conversion and efficiency.

Optimizing turbine efficiency leads to reduced fuel consumption, lower operational costs, increased power output, and enhanced reliability.