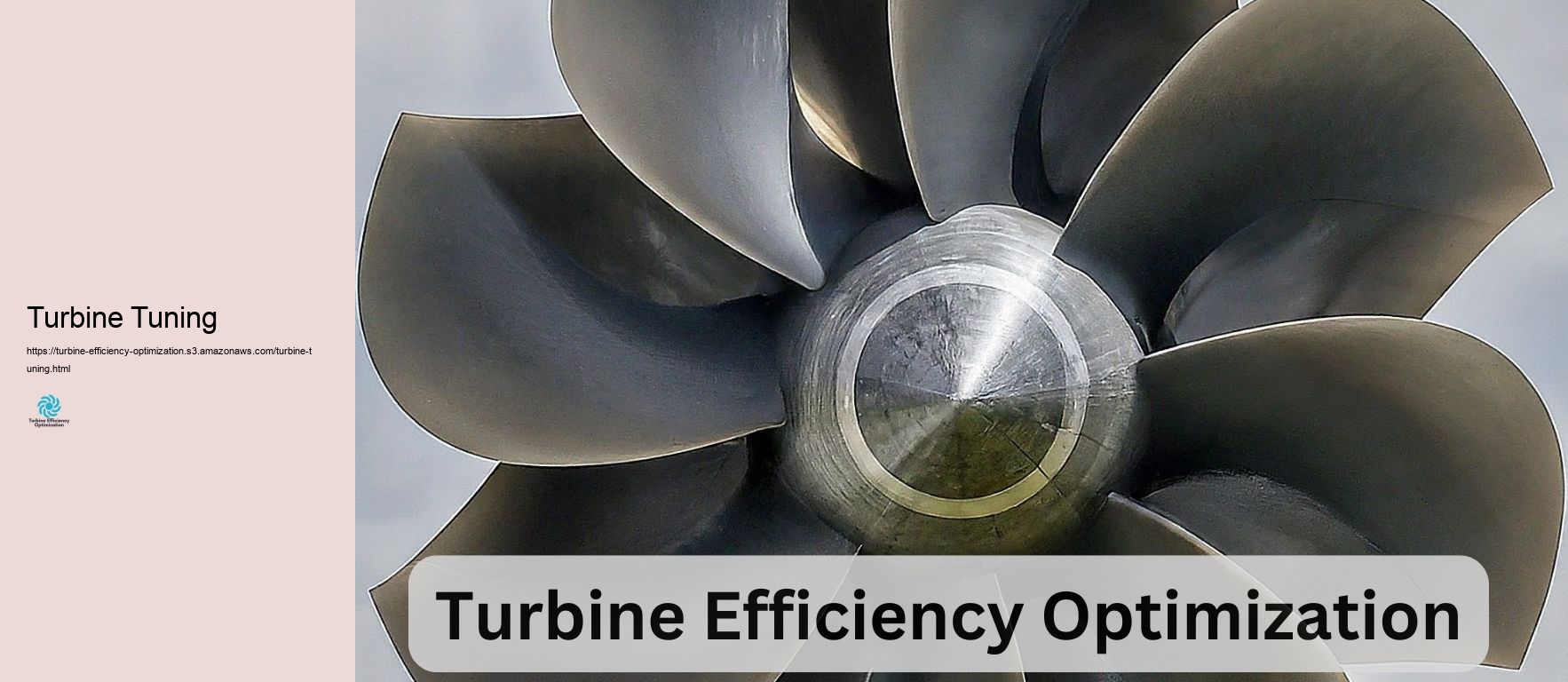

Turbine efficiency is an essential principle in the area of power manufacturing and mechanical design. It describes the capacity of a turbine to transform the power of a moving fluid (such as water, vapor, or gas) right into valuable mechanical task. Comprehending the principles of turbine efficiency is essential for designers, energy specialists, and any individual related to the design, operation, or maintenance of power generation systems. At its core, turbine efficiency is a step of exactly just how effectively a turbine can extract power from the liquid travelling through it. This efficiency is normally shared as a portion, with better percentages revealing much much better performance. In an ideal globe, a turbine would be able to convert 100% of the liquid energy into mechanical job. Nonetheless, in reality, many aspects add to power losses, triggering effectiveness that are regularly much less than 100 %.

Secret variables affecting turbine efficiency encompass a variety of technological, environmental, and functional factors to take into consideration that collectively develop the efficiency and performance of both gas and wind turbines. These variables are important in maximizing the efficiency of wind turbines, which are pivotal in power generation, whether with changing kinetic wind power into electrical power or taking advantage of the thermal energy from gas melting in gas wind generators. For gas generators, one of among the most significant elements affecting performance is the ambient air temperature degree and website altitude. Gas generators are air-breathing engines, indicating that the thickness and mass circulation of the air intake right influence their performance. Higher ambient temperature level degrees decrease air density, causing lowered mass circulation and, consequently, decreased power result. In a similar way, higher altitudes lead to reduced air pressure, additional decreasing air thickness and affecting turbine efficiency. Consequently, comprehending and mitigating the results of these ecological problems using format variables to think about or useful modifications is essential for keeping optimal efficiency. Dampness is another ecological variable that effects gas turbine efficiency. Moist air is much less thick than entirely dry air, which can reduction the mass flow cost by means of the turbine and reduce power outcome. This factor is specifically essential in areas with high wetness levels, where the efficiency of gas wind generators can be jeopardized. To neutralize these influences, some wind turbines are geared up with inlet air cooling systems, such as evaporative coolers or refrigerators, to enhance air density and enhance performance. The kind and premium quality of gas used in gas generators in addition play an essential feature in recognizing efficiency. Numerous fuels have varying calorific well worths, compositions, and burning features, every one of which impact the thermal efficiency and power output of the turbine. Assuring that the fuel meets specific high quality requirements and works with the turbine's layout is critical for completing maximum efficiency. In addition, taking advantage of sophisticated gas heating systems can boost the mixed cycle efficiency by enhancing the power material of the gas. Mechanical losses, such as massaging between relocating elements like bearings and seals, can likewise impact turbine efficiency. These losses are normally decreased throughout the design phase via accuracy engineering and utilizing top quality products. Routine maintenance is vital to ensure that these aspects stay in great trouble, therefore lowering mechanical losses and protecting efficiency. In the context of wind generators, wind price and instructions are one of the most crucial variables impacting performance. Wind wind turbines transform the kinetic power of the wind into electric power, and the quantity of power recorded is directly symmetrical to the wind rate. Additionally small increases in wind speed can cause significant gains in power output. Subsequently, selecting websites with regular and strong wind troubles is exceptionally crucial for optimizing turbine efficiency. The orientation of the turbine relative to the wind direction furthermore impacts performance, demanding resilient yaw control systems to keep excellent placement. Air density and temperature level similarly affect wind turbine efficiency, comparable to gas generators. Greater air density boosts the mass flow price through the turbine, boosting power output. On the other hand, higher temperatures can cause thermal development of products, possibly impacting the efficiency of the generator and various other electrical elements. Audit for these variations through design and functional methods is crucial for boosting performance. Turbulence and wake influences are included variables that can influence wind turbine efficiency. Disruption defines the disorderly variants in wind rate and instructions, which can reason resonances and anxiety on turbine parts, potentially cause tiredness and noise. Wake outcomes take place when the wind price and directions are changed by the presence of upstream generators, affecting the performance of downstream units in a wind ranch. To decrease these impacts, cautious intending of turbine style and spacing, in addition to sophisticated control methods, are necessary. Control and optimization strategies are necessary for both gas and wind generators to achieve optimum efficiency. Cooling systems These techniques entail making use of innovative algorithms and control systems to manage different useful specifications, such as blade pitch, blades rate, and generator torque. By continuously keeping track of and transforming these standards based upon real-time information, generators can run a lot more effectively and accurately, making best use power outcome and minimizing wear and tear. Lastly, ecological and social affects are essential considerations in turbine efficiency. For wind generators, factors such as land use, wild animals interactions, and audio levels can impact public acceptance and controling conformity. For gas wind turbines, wears down and source consumption are vital environmental issues. Dealing with these impacts with lasting practices and stakeholder involvement is required for the lasting feasibility of turbine work. The efficiency of generators, whether gas or wind, is influenced by a complex interaction of ecological, technological, and functional elements. By acknowledging and improving these variables, vehicle drivers can boost efficiency, dependability, and sustainability, guaranteeing that wind turbines remain to play a necessary obligation in the worldwide power landscape. Whether using progressed control systems, essential website selection, or cutting-edge style services, the quest of perfect turbine performance is a dynamic and constant procedure that calls for constant change and enhancement.

Boost turbine performance and efficiency with advanced optimization techniques! Discover the latest strategies in design, materials, and technology to maximize energy output and minimize losses. Stay ahead in the evolving landscape of power generation.https://t.co/pZr0jaoH1i

— Turbine Training And Operation (@turbinetraine) August 25, 2024

Enhancing turbine efficiency is an essential objective in various sectors, including power generation, aerospace, and production, as it directly impacts efficiency, cost-effectiveness, and environmental sustainability. Advanced approaches for turbine efficiency enhancement focus on enhancing layout, materials, and functional strategies to maximize power result while minimizing losses. Right below, we check out a number of advanced methods that are transforming turbine development and pushing the limitations of efficiency. One of the most trustworthy means to boost turbine efficiency is with wind immune optimization.

Preserving optimum turbine procedure is important for ensuring dependable power making, reducing downtime, and extending the life-span of these challenging equipments. Reliable upkeep approaches are essential for nuclear reactor, wind ranches, and industrial facilities that depend on wind turbines for their procedures. By using a considerable maintenance strategy, operators can make ideal use efficiency, decrease prices, and increase general dependability. Among the vital maintenance strategies for optimum turbine operation is the application of a long lasting expecting maintenance program. This approach uses innovative monitoring innovations and information analytics to expect feasible concerns prior to they result in failings or considerable efficiency damage. Noticing systems and keeping an eye on systems are set up throughout the turbine to accumulate real-time data on various standards such as resonance, temperature degree, stress, and oil problem. This details is then analyzed using sophisticated formulas and expert system techniques to acknowledge patterns and problems that could show developing difficulties. Expecting upkeep permits vehicle drivers to set up upkeep activities based upon the actual issue of the tools instead of depending only on repaired time intervals. This method assists stay clear of unexpected failings, decreases unnecessary maintenance, and maximizes using resources. By addressing problems early, operators can stop a lot more considerable and expensive repairings down the line, eventually enhancing the turbine's general stability and efficiency. Regular inspections and problem assessments establish an added vital aspect of reliable turbine upkeep techniques. These evaluations need to be executed at taken care of intervals and consist of both aesthetic assessments and non-destructive testing techniques. Visual evaluations can recognize evident signs of wear, damages, or rust, while non-destructive testing methods such as ultrasonic screening, magnetic fragment examination, and swirl current screening can uncover shock defects or inner issues in necessary parts. During these assessments, specific attention ought to be paid to high-stress locations and components recognized to be susceptible to use or failing. This consists of turbine blades, bearings, transmissions, and seals. By determining and taking care of potential troubles early, vehicle drivers can stop little problems from increasing into significant failures that can lead to expanded downtime and considerable repair costs. Executing a considerable lubrication management program is vital for maintaining ideal turbine operation. Suitable lubrication is crucial for decreasing rubbing, dissipating heat, and safeguarding parts from wear and corrosion. This program must contain typical oil evaluation to display the issue of lubricating substances and area any kind of indicators of contamination or degradation. Fuel efficiency Oil examples need to be taken and examined at regular durations to track adjustments in viscosity, acidity, and the presence of wear pieces or contaminants. Based upon the outcomes of oil analysis, drivers can determine when oil adjustments or filtration are vital, ensuring that the turbine constantly runs with clean, costs lubricants. In addition, the lubrication program should consist of appropriate storage space and taking care of treatments for lubricating materials to prevent contamination and preserve their efficiency. Resonance keeping an eye on and examination is an extra important element of turbine maintenance approaches. Excessive vibration can show numerous concerns, including inequality, imbalance, birthing wear, or loose components. By continually keeping track of resonance levels and patterns, operators can place creating issues early and take restorative activity prior to they cause more extreme damages or stopping working. Advanced vibration analysis strategies, such as spooky analysis and orbit stories, can supply extensive understandings right into the nature and location of possible problems. This details authorizations maintenance groups to concentrate their campaigns on information aspects or areas of problem, improving the efficiency and efficiency of upkeep'' jobs. Thermal imaging is another useful gadget in the maintenance collection for optimal turbine procedure. Normal thermal examinations can find hot spots or irregular temperature level patterns that may show issues such as insulation damage down, electric mistakes, or birthing troubles. By recognizing these issues early, chauffeurs can safeguard versus feasible failures and optimize the turbine's thermal efficiency. Applying a resilient extra parts administration system is important for decreasing downtime and making certain quick action to maintenance needs. This system should consist of an in-depth inventory of essential elements, with clear standards for supply degrees, reordering treatments, and storage space problems. By keeping a sufficient supply of critical spare parts on-hand, chauffeurs can substantially reduced the moment required to complete repair service solutions and return the turbine to option. Training and ability growth for upkeep staff members is an essential however typically overlooked aspect of trusted turbine upkeep techniques. Persisting training programs must be executed to ensure that upkeep personnel are up-to-date with the most recent modern-day technologies, perfect approaches, and security and safety and security treatments. This includes both technical capacities pertaining to turbine upkeep and soft skills such as analytic and interaction. Regular performance testing and efficiency tracking are important for protecting optimal turbine treatment. These examinations can help establish any kind of destruction in efficiency in time and authorization operators to take corrective activity to recover the turbine to come to a head efficiency. Efficiency screening should contain dimensions of power result, fuel intake, and discharges degrees'., in addition to analyses of private component efficiency. Performing an electronic maintenance administration system (CMMS) can substantially increase the effectiveness of turbine upkeep approaches. A CMMS can help boost maintenance organizing, track work orders, take care of supply, and supply valuable info for assessment and decision-making. By integrating upkeep information and automating several regular jobs, a CMMS can increase general upkeep efficiency and aid ensure that no important upkeep tasks are disregarded. Lastly, it's vital to often take a look at and upgrade upkeep techniques to integrate new technologies, best techniques, and lessons learned from past experiences. This continual improvement technique assurances that upkeep programs remain to be reliable and

reliable when faced with proceeding technologies and modifying useful requirements. Maintaining excellent turbine treatment requires a complicated approach that includes anticipating maintenance, routine assessments, lubrication management, resonance checking, thermal imaging, spare parts management, workers training, performance screening, and the use of innovative administration systems. By performing these approaches, drivers can enhance turbine reliability, efficiency, and long life, certainly produce boosted useful efficiency and reduced expenditures.

Innovative innovations in turbine efficiency optimization are transforming the landscape of power producing, supplying new methods to enhance performance, minimize ecological influence, and enhance the sustainability of power generation systems. As globally demand for reliable and clean power alternatives remains to boost, advancements in turbine technology are becoming increasingly important. These innovations cover a series of locations, consisting of products clinical study, digital modern technology, melting procedures, and aerodynamic design, each adding to the general efficiency and effectiveness of generators taken advantage of in numerous applications, from nuclear power plant to wind cattle ranches. Among one of the most substantial advancements in turbine efficiency optimization is making use of innovative products and finishings. Wind wind turbines run under extreme conditions, with heats and pressures that conventional materials can not withstand without damaging down. Technologies in items clinical study have caused the innovation of superalloys, especially those based on nickel, which keep their stamina and security at elevated temperatures. These products expand the life span of turbine aspects and permit them to run at better performance. Additionally, thermal obstacle coverings (TBCs), such as sophisticated ceramic substances, are related to turbine components to safe them from warm and boost their strength. These surfaces job as insulators, keeping the steel elements cooler and boosting their performance under rough issues. Additive producing, or 3D printing, is transforming the production and maintenance of turbine elements. This modern-day technology allows for the production of complex, high-precision components that are tough or difficult to make making use of typical strategies. Additive production makes it possible for quick prototyping, allowing developers to quickly make, examination, and improve turbine parts, boosting the growth treatment. The capability to generate components as required reductions the need for huge supplies of spare components and decreases downtime, as substitute parts can be manufactured and mounted without delay. Additionally, additive manufacturing advertises the production of elements with sophisticated geometries that maximize airflow and cooling within the turbine, better enhancing efficiency and reducing thermal tension. The mix of digital technologies into turbine procedures has actually opened up brand-new techniques for efficiency optimization. Digital twins, digital recreations of physical wind turbines, allow drivers to mimic and check turbine efficiency in real-time. By analyzing info from sensing units and electronic twins, expecting upkeep formulas can prepare for when a turbine aspect is most likely to fail, enabling maintenance to be scheduled at ideal times. This proactive technique decreases downtime and maintenance costs while making certain that wind generators operate at peak efficiency degrees. Expecting maintenance not simply expands the life expectancy of turbine components nonetheless in addition maximizes efficiency by staying clear of unexpected failings and enhancing useful standards. Dope in burning modern technology are important to boosting turbine efficiency and lowering eco-friendly result. Common combustion processes in generators create nitrogen oxides (NOx), unsafe toxic substances that add to air contamination. Engineers have really established low-NOx combustors that minimize NOx growth by enhancing the burning treatment. These advanced combustors utilize methods such as lean-burn methods and improved fuel-air blending to reduction discharges without endangering efficiency. As the globe changes to cleaner energy sources, hydrogen is ending up being an appealing gas for generators. Hydrogen combustion creates simply water vapor as a result, eliminating carbon dioxide tires.

Making the most of turbine format for maximum efficiency is a diverse undertaking that includes a deep understanding of aerodynamic principles, product scientific research, thermodynamics, and innovative engineering techniques. Whether managing gas wind generators taken advantage of in power plants and plane or wind generators utilizing renewable energy, the unbiased is to convert power resources right into mechanical or electric power with the biggest possible efficiency. Achieving this calls for a comprehensive approach that thinks about every facet of the turbine's design, from the type and products of the blades to the arrangement of the whole system. For gas generators, efficiency optimization starts with the design of the compressor and turbine blades. These blades have to be faithfully crafted to sustain heats up and pressures while decreasing wind immune drag. Advanced computational fluid features (CFD) simulations are made use of to layout air flow over the blades, permitting designers to improve their kind for optimum performance. Utilizing high-performance items, such as sophisticated alloys and ceramics, enables blades to operate at greater temperature level levels, which is critical for enhancing thermal efficiency. Additionally, consisting of cooling modern technologies, such as movie a/c or transpiration cooling, aids protect blade stability under extreme problems, additionally improving efficiency. The burning chamber is an additional important part in gas turbine design. It needs to be made to make certain full and effective shedding of the gas, reducing discharges and maximizing power result. Advancements such as lean-burn melting contemporary technology, which decreases the amount of excess air in the burning procedure, can drastically enhance efficiency and reduce nitrogen oxide tires. Additionally, the mix of innovative control systems enables precise policy of gas and air blends, boosting burning problems in real-time based upon running specifications. In the context of wind generators, enhancing layout for optimal efficiency includes a concentrate on the rotor blades, which are accountable for tape-recording the kinetic power of the wind. The wind resistant shape of the blades is vital; they should be made to maximize lift while minimizing drag.

Turbine efficiency is impacted by factors such as blade design, fuel quality, operating conditions, and maintenance practices.

Turbine efficiency can be optimized through regular maintenance, performance monitoring, upgrading components, and using advanced control systems.

Predictive maintenance helps identify potential issues before they affect efficiency, reducing downtime and improving overall turbine performance.

Blade design is crucial as it directly affects the aerodynamic performance of the turbine, influencing energy conversion and efficiency.

Optimizing turbine efficiency leads to reduced fuel consumption, lower operational costs, increased power output, and enhanced reliability.