Turbine efficiency is a necessary idea in the location of power manufacturing and mechanical layout.

experts needs to take into consideration all these aspects to style, run, and protect generators that accomplish the biggest feasible efficiency. As advancement stays to improvement and our understanding of liquid features and power conversion expands, we can expect even more renovations in turbine efficiency, contributing to much more lasting and effective power making systems worldwide.

Secret aspects affecting turbine efficiency include a variety of technical, ecological, and operational considerations that collectively develop the efficiency and effectiveness of both gas and wind generators. These factors are critical in making best use of the efficiency of generators, which are essential in power generation, whether with transforming kinetic wind power right into electrical power or making use of the thermal power from gas melting in gas wind turbines. For gas wind generators, among among one of the most significant variables affecting performance is the ambient air temperature and website altitude. Gas generators are air-breathing engines, implying that the density and mass flow of the air consumption directly influence their efficiency. Greater ambient temperature degrees reduced air thickness, causing reduced mass blood circulation and, subsequently, lowered power outcome. In a similar means, higher elevations cause decreased atmospheric pressure, a lot more lowering air thickness and affecting turbine efficiency. As a result, recognizing and mitigating the outcomes of these environmental problems using design factors to consider or operational adjustments is important for keeping optimal efficiency. Dampness is another environmental variable that impacts gas turbine efficiency. Damp air is a lot less thick than completely dry air, which can reduced the mass flow rate with the turbine and decrease power result. This element is specifically relevant in regions with high moisture degrees, where the efficiency of gas turbines can be jeopardized. To combat these influences, some wind turbines are supplied with inlet air cooling systems, such as evaporative colders or fridges, to enhance air thickness and improve performance. The kind and top quality of gas utilized in gas wind turbines likewise play a crucial duty in determining efficiency. Different gas have varying calorific worths, make-ups, and burning characteristics, every one of which affect the thermal efficiency and power outcome of the turbine. Making certain that the gas satisfies details high quality standards and works with the turbine's style is needed for acquiring perfect efficiency. Furthermore, using sophisticated gas heating device can increase the consolidated cycle efficiency by enhancing the power web material of the gas. Mechanical losses, such as friction between moving parts like bearings and seals, can additionally impact turbine efficiency. These losses are commonly lessened throughout the style phase through accuracy style and making use of costs materials. Routine maintenance is vital to guarantee that these components stay in terrific trouble, consequently reducing mechanical losses and maintaining efficiency. In the context of wind generators, wind rate and instructions are one of the most crucial facets influencing performance. Wind wind generators change the kinetic energy of the wind right into electrical power, and the amount of power tape-recorded is right symmetrical to the wind price. Also little increases in wind rate can cause significant gains in power result. For that reason, picking websites with consistent and solid wind conditions is extremely important for making ideal use turbine efficiency. The placement of the turbine regarding the wind guidelines also effects efficiency, requiring sturdy yaw control systems to preserve optimal placing. Air thickness and temperature furthermore impact wind turbine efficiency, similar to gas generators. Higher air thickness increases the mass flow price with the turbine, enhancing power result.

Boost turbine performance and efficiency with advanced optimization techniques! Discover the latest strategies in design, materials, and technology to maximize energy output and minimize losses. Stay ahead in the evolving landscape of power generation.https://t.co/pZr0jaoH1i

— Turbine Training And Operation (@turbinetraine) August 25, 2024

Enhancing turbine efficiency is an important unbiased in many sectors, consisting of power generation, aerospace, and production, as it directly effects performance, cost-effectiveness, and environmental sustainability. Advanced strategies for turbine efficiency improvement concentrate on optimizing layout, materials, and functional strategies to maximize power result while lowering losses. Right right here, we take a look at a variety of sophisticated methods that are changing turbine technology and pushing the boundaries of efficiency.

Maintaining optimal turbine operation is vital for making sure effective power production, minimizing downtime, and extending the life-span of these difficult equipments. Effective maintenance strategies are crucial for nuclear reactor, wind cattle ranches, and industrial centers that trust turbines for their operations. By executing a thorough upkeep approach, drivers can make best use of efficiency, reduce costs, and boost complete stability. Among the vital maintenance strategies for optimum turbine procedure is the application of a long lasting expecting maintenance program. This method makes use of advanced surveillance advancements and data analytics to prepare for prospective worries prior to they cause failings or significant efficiency damage.

reliable in the face of advancing innovations and altering functional needs. Preserving ideal turbine treatment requires a complicated strategy that integrates predictive maintenance, routine assessments, lubrication checking, resonance surveillance, thermal imaging, extra parts management, employees training, efficiency testing, and making use of sophisticated checking systems. By executing these approaches, vehicle drivers can take advantage of turbine reliability, efficiency, and longevity, at some point resulting in enhanced operational efficiency and minimized costs.

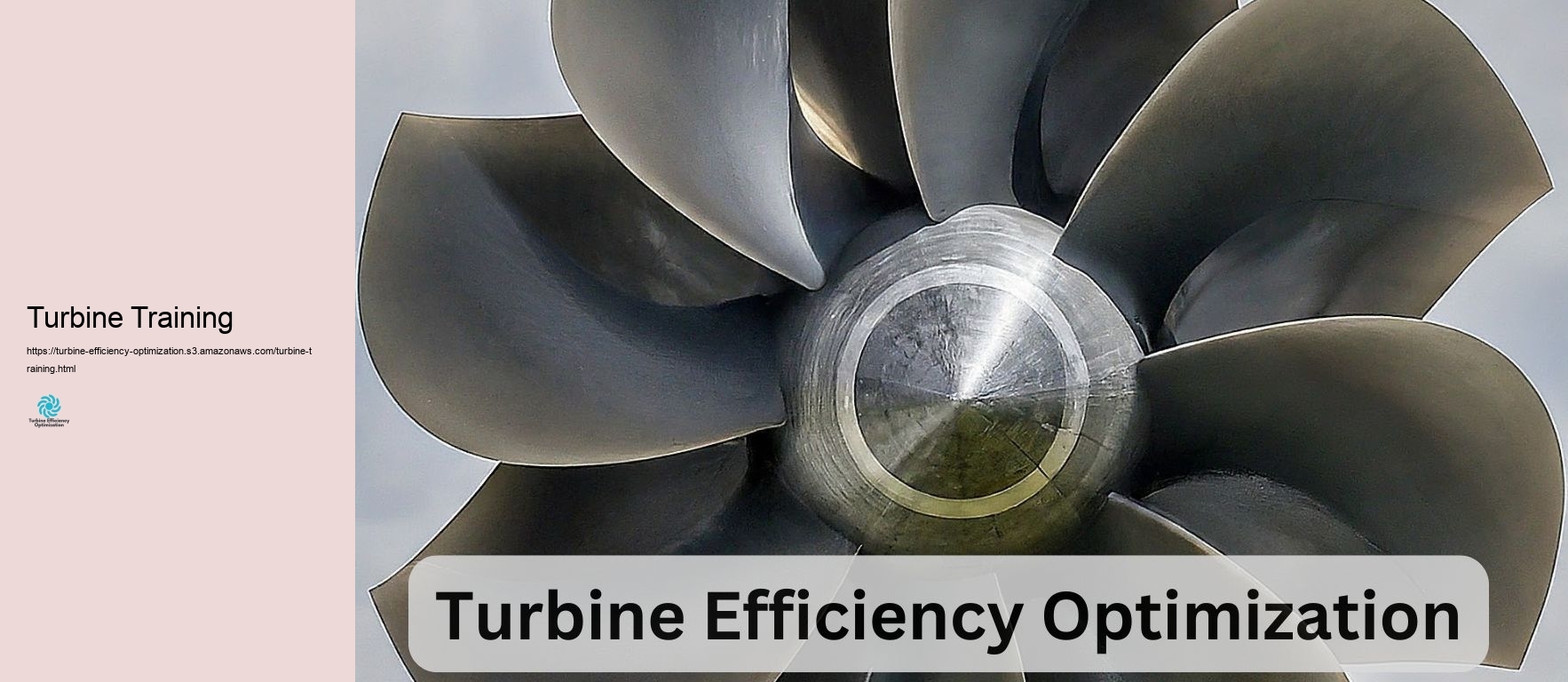

Resourceful technologies in turbine efficiency optimization are transforming the landscape of power making, giving brand-new techniques to enhance efficiency, lower ecological impact, and enhance the sustainability of power generation systems. As worldwide need for trusted and tidy power alternatives remains to climb, growths in turbine modern technology are ending up being progressively important. These technologies expand a collection of areas, consisting of materials clinical research study, electronic advancement, combustion processes, and wind immune style, each adding to the overall efficiency and efficiency of generators made use of in various applications, from nuclear power plant to wind cattle ranches. Among among one of the most considerable advancements in turbine efficiency optimization is making use of innovative products and coatings. Generators run under extreme issues, with high temperatures and pressures that conventional products can not withstand without damaging. Advancement in items scientific research have really caused the advancement of superalloys, specifically those based upon nickel, which preserve their endurance and stability at elevated temperature level levels. These products prolong the life span of turbine elements and allow them to run at higher performances. Additionally, thermal barrier finishings (TBCs), such as innovative ceramic composites, are placed on turbine parts to secure them from warm and improve their resilience. These finishings act as insulators, keeping the steel components cooler and boosting their efficiency under rough problems. Additive production, or 3D printing, is reinventing the manufacturing and upkeep of turbine parts. This technology allows for the development of facility, high-precision elements that are challenging or challenging to create using basic strategies. Additive manufacturing makes it possible for fast prototyping, allowing developers to rapidly create, evaluation, and boost turbine aspects, speeding up the development procedure. The capability to generate components on demand decreases the requirement for large supplies of extra parts and lowers downtime, as substitute elements can be manufactured and placed quickly. In addition, additive manufacturing promotes the production of elements with intricate geometries that enhance air flow and cooling within the turbine, further improving efficiency and decreasing thermal stress and anxiety and anxiety. The assimilation of electronic developments right into turbine procedures has opened up brand-new methods for efficiency optimization. Digital doubles, on the internet replicas of physical generators, permit drivers to duplicate and check turbine performance in real-time. By reviewing information from sensors and electronic doubles, anticipating upkeep algorithms can projection when a turbine aspect is more than likely to stop working, allowing maintenance to be scheduled at optimal times. This positive approach lessens downtime and upkeep expenditures while assuring that wind turbines run at peak efficiency degrees. Expecting maintenance not simply expands the life expectancy of turbine components yet furthermore makes best use of efficiency by safeguarding versus unexpected failings and improving useful specifications. Innovations in shedding modern-day innovation are important to improving turbine efficiency and reducing environmental effect. Standard shedding procedures in generators generate nitrogen oxides (NOx), dangerous toxic substances that contribute to air air pollution. Designers have in fact created low-NOx combustors that lower NOx development by maximizing the combustion process. These advanced combustors use techniques such as lean-burn approaches and improved fuel-air mixing to reduced exhausts without endangering efficiency. As the globe transitions to cleaner energy sources, hydrogen is coming to be an encouraging gas for generators. Hydrogen burning generates only water vapor as a result, eliminating CARBON DIOXIDE discharges. Technologies in hydrogen burning contemporary technology are making it possible for wind turbines to run effectively with this clean gas, adding to an additional lasting power landscape. The wind resistant design of turbine blades plays a crucial obligation in establishing the efficiency and performance of both gas and wind generators. Developments in the rules of aerodynamics and blade style have in fact brought about substantial renovations in turbine efficiency. Designers take advantage of computational liquid dynamics (CFD) and 3D printing to develop aerodynamically made best use of blade formats that boost the flow of air and gases with the turbine, decreasing energy losses and enhancing overall efficiency. In wind turbines, variable pitch and spin designs enable blades to adjust dynamically to changing wind troubles, boosting efficiency and lowering mechanical stress.

Optimizing turbine design for optimum efficiency is a complicated undertaking that involves a deep understanding of wind immune ideas, item science, thermodynamics, and sophisticated design approaches. Whether looking after gas generators made use of in power plants and airplane or wind generators using renewable resource, the goal is to transform power resources right into mechanical or electrical power with the highest viable efficiency. Acquiring this require a comprehensive technique that considers every component of the turbine's design, from the type and items of the blades to the configuration of the entire system. For gas generators, efficiency optimization starts with the design of the compressor and turbine blades. These blades should be carefully engineered to sustain high temperatures and stress while decreasing wind immune drag. Advanced computational liquid dynamics (CFD) simulations are made use of to design air flow over the blades, allowing engineers to enhance their form for perfect efficiency. Using high-performance products, such as cutting-edge alloys and porcelains, enables blades to run at higher temperature levels, which is crucial for boosting thermal efficiency. In addition, incorporating cooling innovations, such as movie a/c or transpiration cooling, helps preserve blade integrity under severe troubles, furthermore enhancing efficiency. The melting chamber is an extra essential component in gas turbine design. It must be created to make certain complete and reliable burning of the gas, lowering discharges and making ideal use of power outcome. Technologies such as lean-burn shedding modern-day technology, which declines the quantity of excess air in the burning procedure, can significantly boost efficiency and decrease nitrogen oxide exhausts. Energy audits Furthermore, the assimilation of advanced control systems permits precise guideline of fuel and air mixes, optimizing burning conditions in real-time based upon running standards. In the context of wind generators, maximizing format for ideal efficiency entails a focus on the rotor blades, which are accountable for videotaping the kinetic power of the wind. Turbine Training The aerodynamic form of the blades is extremely important; they need to be produced to optimize lift while decreasing drag. This frequently includes the use of airfoil forms that are improved for particular wind problems. Designers make use of wind tunnel screening and CFD simulations to make renovations blade layouts, guaranteeing they perform effectively across a series of wind prices. On top of that, taking advantage of light-weight composite products, such as carbon fiber or fiberglass, decreases the overall weight of the blades, allowing them to react even more dynamically to alterations in wind problems and boosting complete efficiency. The height and placement of wind generators are also important factors in improving efficiency. Taller towers allow turbines to access to greater wind speeds, which are commonly far more regular and efficient. Web site option, therefore, requires mindful evaluation of wind patterns and topography to warranty wind turbines are positioned where they can catch the most energy. In wind cattle ranches, the layout of generators need to be purposefully intended to reduction wake results, where the disturbance created by one turbine effects the efficiency of others downwind. By boosting the spacing and placing of generators, power capture can be maximized across the whole ranch. Control systems play an important feature in maximizing turbine efficiency, both for gas and wind turbines. For gas wind generators, advanced control systems watch on and change specs such as gas flow, air intake, and exhaust temperature levels to maintain optimum running troubles. These systems can reply to modifications popular and ecological conditions, guaranteeing that the turbine operates at peak efficiency in all times. In wind generators, control systems modification the pitch of the blades and the yaw of the nacelle to correct with transforming wind instructions and rates, maximizing power capture while decreasing mechanical anxiety. Power storage space and hybrid systems are emerging as necessary variables to take into consideration in turbine style, especially for renewable energy applications. Incorporating power storage space solutions, such as batteries or flywheels, can aid smooth out the variability of wind power, keeping excess power throughout durations of high manufacturing and launching it when requirement is greater. Crossbreed systems that incorporate wind generators with various other power resources, such as photovoltaic panels or gas generators, can provide a lot more regular power result and enhance complete efficiency. The assimilation of digital advancements and information analytics is transforming turbine design and operation. Utilizing noticing devices and IoT devices makes it possible for real-time monitoring of turbine efficiency, providing useful info that can be utilized to maximize procedure and maintenance. Predictive analytics can determine possible issues prior to they result in failings, permitting aggressive upkeep that lessens downtime and extends the life span of the turbine. Artificial intelligence formulas can evaluate significant quantities of data to identify patterns and enhance control methods, further boosting efficiency. Enhancing turbine design for maximum efficiency is a facility and dynamic process that requirements an all natural strategy, considering everything from wind immune style and product selection to control systems and digital assimilation. By leveraging sophisticated technologies and engineering concepts, turbine developers can establish systems that transform power resources into power with unrivaled efficiency, adding to a much more lasting and trustworthy power future. Whether in the context of gas generators driving business applications or wind generators using renewable energy, the pursuit of maximum efficiency stays a crucial objective that drives development and growth in the area.

Turbine efficiency is impacted by factors such as blade design, fuel quality, operating conditions, and maintenance practices.

Turbine efficiency can be optimized through regular maintenance, performance monitoring, upgrading components, and using advanced control systems.

Predictive maintenance helps identify potential issues before they affect efficiency, reducing downtime and improving overall turbine performance.

Blade design is crucial as it directly affects the aerodynamic performance of the turbine, influencing energy conversion and efficiency.

Optimizing turbine efficiency leads to reduced fuel consumption, lower operational costs, increased power output, and enhanced reliability.